Re: 87 bayliner refurb/restoration project... "The Big Dirty"

Ok folks, I'm getting ready to start on the cabin floor, looking for thoughts and theory's, ideas, or even constructive "OH MY GOD NO! DONT DO IT LIKE THAT!!" comments...:lol:

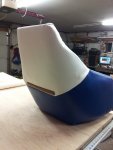

Heres my plan at this pint.. er, point.. I have measured it out, and believe i have just enough hardwood to cover the whole thing. (freebe, leftovers from a friends house, 3/4" oak, nice stuff.. a piece is sitting there in the first pic) The curved side will be a lot of custom cuts, but I think its the only way it will look good in the end. The hull curves/tapers up from there so I don't see another option.. I'll start the new carpet there, and along with everything else it will get re carpeted in a light grey of some sort. Anyway, after the rest of the original gawd awful carpet is removed, i'm going to 'square off' the cut section of the floor and build back/scab in what and where I need, to end up with a roughly 6 foot long by 15" opening. (I originally told the glass guy 'just cut out what you need to, i don't care'.. sort of regretting that now.. he nicked my stringers in a few spots, so I'll have to repair/cover that first, but i can sill work ahead regardless at this point.) In the end i'd like two removable floor hatches, or panels, so I can easily access that area of the boat if need be. It will also make it easier on one hand, as I can easily handle smaller pieces, and work away in a WARM garage.. for the most part anyway.

It's not shown in the first pic, but back by the cabin entrance is the pump and raw water pickup for the head, and the front bilge pump is at the top of the pic there too.. (the factory 5" square access was kinda silly Imo..) Seeing as this area of the boat was/is prone to collecting water, but its basically SEALED from the factory I've elected to make an improvement here.. thats my story and I'm sticking to it.

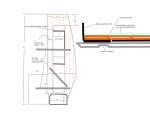

So; I'm thinking of just gluing the hardwood to the factory floor, around the opening I create, and screwing/gluing the hardwood to the panels i will build, leaving about a 3/4" overhang on the sides. i hesitate to screw the permanent pieces to the boat, as it is literally right on the hull.. a few screws punching through the hull would just suck. Maybe its overkill, but I notice the floor REALLY flexes at this point, so I'm thinking of adding some aluminum angle crossers underneath for support of the whole thing in general, and to support the removable panels.

The factory only put a few 2x2 pieces of wood across, one by the aft cabin door and one about where the fridge is.. just don't seam tough enough for me.. and the rear most bulkhead is new as well, there was nothing there from the factory which I consider either a design flaw, or perhaps it was 'forgotten' during the build? Its literally a 6 foot + span from the first bulkhead back to the firewall/cabin entrance..

I just see that section of the hull taking a lot of the pounding while running.. second pic is my ms paint 'schematic' drawing/idea :laugh: NTS but hopefully you get the idea..