- Joined

- Jul 18, 2011

- Messages

- 18,915

OK, my gasoline to pour onto the fire. . .

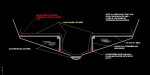

As far as the structure, and for the OP's consideration, any of the darkened areas of stringer and bulkhead, yet still 'solid' are the beginning stages of rot. (so, port side stinger and rear bulkhead) Options are to:

1) replace that piece of the structure

Or

2) treat with 'chemotherapy' Ethylene Glycol to inhibit further deterioration

As far as the fuel tank and its surrounding structure . . .

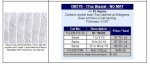

The USGC reg cited states that you cannot built a fuel tank out of the boat's structure, i.e. form a tank from the bulkhead and stringers and put a cover over it to make it a tank. You must use a separate tank.

It does not state (as least from what I can see) that the 'coffin' where the fuel tank lies within has to be water or air tight, nor that drainage cannot be provided (if that is the question at hand :noidea: ). Just about all of them are not air tight.

As far as the structure, and for the OP's consideration, any of the darkened areas of stringer and bulkhead, yet still 'solid' are the beginning stages of rot. (so, port side stinger and rear bulkhead) Options are to:

1) replace that piece of the structure

Or

2) treat with 'chemotherapy' Ethylene Glycol to inhibit further deterioration

As far as the fuel tank and its surrounding structure . . .

The USGC reg cited states that you cannot built a fuel tank out of the boat's structure, i.e. form a tank from the bulkhead and stringers and put a cover over it to make it a tank. You must use a separate tank.

It does not state (as least from what I can see) that the 'coffin' where the fuel tank lies within has to be water or air tight, nor that drainage cannot be provided (if that is the question at hand :noidea: ). Just about all of them are not air tight.