j_k_bisson

Lieutenant Junior Grade

- Joined

- Oct 6, 2010

- Messages

- 1,082

Update 11-01-2010

Update 11-01-2010

Well Halloween is over for only 8hrs and 15minute and I heard my first X-mas tune on the radio. God help us!!!! I hope my kids don't hear it for at least a week!

I hope my kids don't hear it for at least a week!

After everything died down last night. Pun intended!!!! I got back to work on buffing the boat. I finished buffing the one side. The transom was done last week, so it only needs a touch up. I have been using the the Meguires system buffing pads. (Maroon, yellow, and white) along with meguires buffing compound, 3M finishing compound, and Meguires wax. Although I have yet to wax anything. I have found that less is more when buffing. Meaning I only use like a half a dime size globe of compound on the pad for a 2 foot area. Then when it get a bit dry, I stick three fingers into a buck of water and wet the pad with 5-10 drops of water renewing the compound. Also I have learned to watch for the pad getting over loaded with compound. My handy screw driver takes care of that though. It is definately a trial and error process that you can not rush at all! But the out come it well worth it. Check out the one side in the picks.

I got back to work on buffing the boat. I finished buffing the one side. The transom was done last week, so it only needs a touch up. I have been using the the Meguires system buffing pads. (Maroon, yellow, and white) along with meguires buffing compound, 3M finishing compound, and Meguires wax. Although I have yet to wax anything. I have found that less is more when buffing. Meaning I only use like a half a dime size globe of compound on the pad for a 2 foot area. Then when it get a bit dry, I stick three fingers into a buck of water and wet the pad with 5-10 drops of water renewing the compound. Also I have learned to watch for the pad getting over loaded with compound. My handy screw driver takes care of that though. It is definately a trial and error process that you can not rush at all! But the out come it well worth it. Check out the one side in the picks.

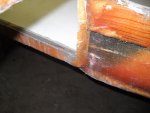

I do have a question on the bottom of my hull. I need to know how to fix the gel coat voids I have. If you look at the pic at the chine you will notice a couple of holes/voids where the gel coat chipped off. How should I fix this? Should I just fix with gel coat repair kits? Or send i out for blasting (nut shell) and go through the whole process of resin and gel coat repair. It anyone has any thoughts, it would be greatly appreciated. I will be getting under there later this week to buff and a better look. So more to follow.

I also can tell you the gel coat repair is alot harder to do than it looks. My first couple of spots I did are not the greatest!!!! But they will do. I'll try to cover them up with graphics if I can!

But they will do. I'll try to cover them up with graphics if I can!

Tonigt I will probably spend with a buffer in my hands for a few long hours! This is after peeling the last graphic on the other side of the boat. I want to trace it before I remove it. I might get my buddy to create a new one. He owns a sign buisness. The tracing will help with actual size verification. But we will see what happens. That is a spring time job. Right now its to get it water worthy!

Update 11-01-2010

Well Halloween is over for only 8hrs and 15minute and I heard my first X-mas tune on the radio. God help us!!!!

After everything died down last night. Pun intended!!!!

I do have a question on the bottom of my hull. I need to know how to fix the gel coat voids I have. If you look at the pic at the chine you will notice a couple of holes/voids where the gel coat chipped off. How should I fix this? Should I just fix with gel coat repair kits? Or send i out for blasting (nut shell) and go through the whole process of resin and gel coat repair. It anyone has any thoughts, it would be greatly appreciated. I will be getting under there later this week to buff and a better look. So more to follow.

I also can tell you the gel coat repair is alot harder to do than it looks. My first couple of spots I did are not the greatest!!!!

Tonigt I will probably spend with a buffer in my hands for a few long hours! This is after peeling the last graphic on the other side of the boat. I want to trace it before I remove it. I might get my buddy to create a new one. He owns a sign buisness. The tracing will help with actual size verification. But we will see what happens. That is a spring time job. Right now its to get it water worthy!