About 3 years ago I took the plunge and fully restored an old 1984 Skeeter. I kept the boat for a while and loved every minute of it. I then took a new job in Colorado and sold the boat (for quite a bit more than I had in it, at that). After a year and a half in Colorado, I took another new job back in Texas.

Now, this initial post is going to be looong and may not have pictures. It probably won't be very entertaining either, but it is a necessary evil. The reason being is that I have a story behind this and I am still not 100% positive just how much "restoring" I am going to do with this. I want to have record of my progress, if for nothing more than posterity.

It didn't take long before catching wind of my next boat. A friend had a boat that he wanted to get rid of. The boat was a 1989 Skeeter SD-125. His dad was the original owner, making me the second owner (on paper) of this 25 years old boat. The boat was well cared for, but still, it's a 25 year old boat.

The boat came with a 1984 Johnson 115hp outboard. It originally had a Suzuki on it, but it blew up many years ago so they put the Johnny on it. At some point a couple of years ago, the lower unit went out. My friend pulled the LU and never got the cash or time to do anything else. The wood seemed OK and the transom seemed ok. I offered my friend $700 for it, knowing that I would need at least a LU. I would have bought the boat regardless to help the friend out, but I secretly hoped it didn't need a restore. I drove away later that evening with boat in tow.

Back in the garage, I started to give a better inspection. Sure, it needs new carpet. Sure, the gelcoat has knicks and scrapes and could use some elbow grease. The floor feels solid, but might have a soft spot by a drain. The trailer needs new bunk boards and a new spare. The motor fired up on the muffs. No obvious structural problems found. I decided to go ahead and get moving on a lower unit rebuild.

I snagged a deal on a banged up lower unit housing here locally and purchased all new internals. I think at that point I was at about $900 total, plus $100 or so on the required stuff (life jackets, rope, etc). We'll call it a $1000 boat. Still fired up fine on the muffs so away we went to the lake for the true test. This is where the indecision for me really starts.

The motor fired up and we had no problem getting on plane. We died a couple of times and idle ended up having a nasty sneeze. I also noticed the bilge took on more water than I care to admit (but not nearly enough to worry about sinking; the pump could handle the volume fine). Steering was rough, and I noticed more spots in the floor that may be soft. I noticed the backs to the seats were in poor condition (I can almost lay straight back in the captains seat). We still had a blast, caught some fish, and had a good swim. Loading the boat back up proved to be interesting. The bunk boards were in worse shape than I thought. Apparently the hardware was rusted out and the bunks were floating as I was coming up. I ended up having to hop in to the water, hook up the bow strap, and hold the bunks down in the right position as I manually pulled the boat in.

So back at the garage I made a temporary solution for the bunk boards and turned my attention to the easy stuff. I cleaned the carbs and tweaked the settings. I lubed up the steering cable. I tightened some fittings around the 2 livewell system. We used the boat a few more times, each time I would tweak a little more. By the end of summer, I had decided it was a keeper so I dropped another $1000 on electronics and I rewired behind the helm and at the bow. I never did get to the bottom of my idle issue, though. In August, I had stripped down most of the engine to try and find the issue, and that is where my progress stopped.

I haven't touched the boat since then. It has sat in the garage, collecting dust and cobwebs. With my busy work schedule, my kids now involved in 2 sports each, and my wife working, I didn't think I would ever have time to fix or even use the boat. I contemplated just ditching the thing for what I have in it, but recently thought better of it and have decided to move on with it. This is where I am going to begin my journey with all of my fellow iBoaters. As mentioned, I don't know just how must restoring I will do or how often I will be able to do it, but I do promise it will be something.

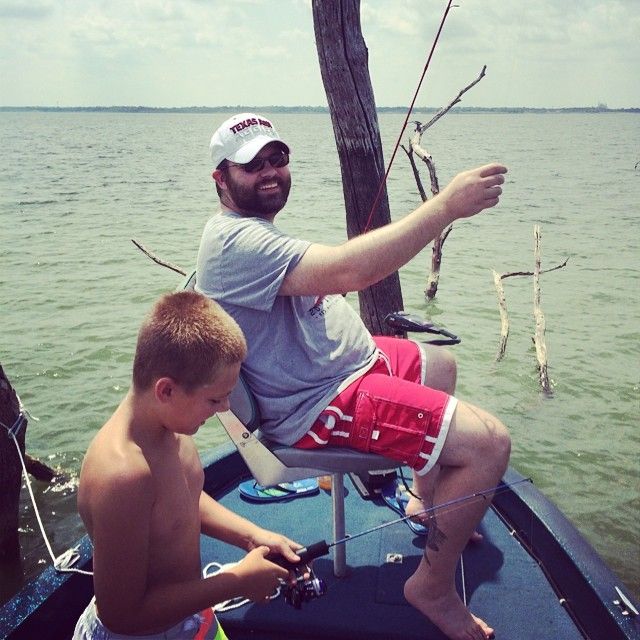

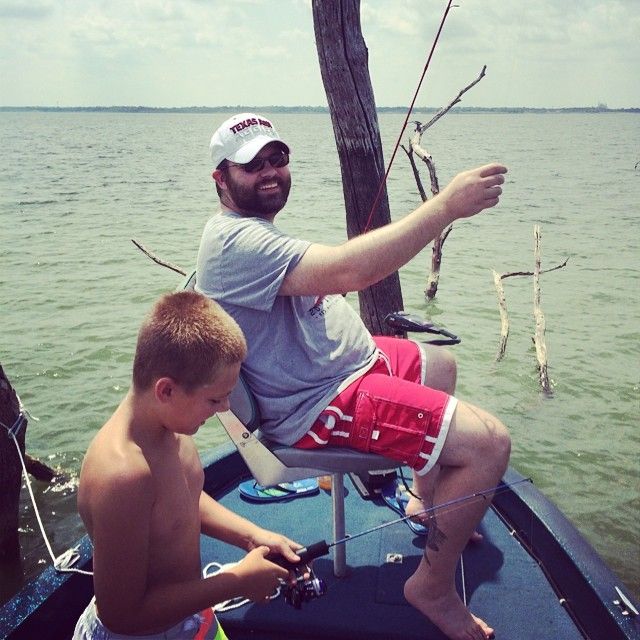

Because I know iBoaters like pictures, here are the only ones I have of the boat.

Now, this initial post is going to be looong and may not have pictures. It probably won't be very entertaining either, but it is a necessary evil. The reason being is that I have a story behind this and I am still not 100% positive just how much "restoring" I am going to do with this. I want to have record of my progress, if for nothing more than posterity.

It didn't take long before catching wind of my next boat. A friend had a boat that he wanted to get rid of. The boat was a 1989 Skeeter SD-125. His dad was the original owner, making me the second owner (on paper) of this 25 years old boat. The boat was well cared for, but still, it's a 25 year old boat.

The boat came with a 1984 Johnson 115hp outboard. It originally had a Suzuki on it, but it blew up many years ago so they put the Johnny on it. At some point a couple of years ago, the lower unit went out. My friend pulled the LU and never got the cash or time to do anything else. The wood seemed OK and the transom seemed ok. I offered my friend $700 for it, knowing that I would need at least a LU. I would have bought the boat regardless to help the friend out, but I secretly hoped it didn't need a restore. I drove away later that evening with boat in tow.

Back in the garage, I started to give a better inspection. Sure, it needs new carpet. Sure, the gelcoat has knicks and scrapes and could use some elbow grease. The floor feels solid, but might have a soft spot by a drain. The trailer needs new bunk boards and a new spare. The motor fired up on the muffs. No obvious structural problems found. I decided to go ahead and get moving on a lower unit rebuild.

I snagged a deal on a banged up lower unit housing here locally and purchased all new internals. I think at that point I was at about $900 total, plus $100 or so on the required stuff (life jackets, rope, etc). We'll call it a $1000 boat. Still fired up fine on the muffs so away we went to the lake for the true test. This is where the indecision for me really starts.

The motor fired up and we had no problem getting on plane. We died a couple of times and idle ended up having a nasty sneeze. I also noticed the bilge took on more water than I care to admit (but not nearly enough to worry about sinking; the pump could handle the volume fine). Steering was rough, and I noticed more spots in the floor that may be soft. I noticed the backs to the seats were in poor condition (I can almost lay straight back in the captains seat). We still had a blast, caught some fish, and had a good swim. Loading the boat back up proved to be interesting. The bunk boards were in worse shape than I thought. Apparently the hardware was rusted out and the bunks were floating as I was coming up. I ended up having to hop in to the water, hook up the bow strap, and hold the bunks down in the right position as I manually pulled the boat in.

So back at the garage I made a temporary solution for the bunk boards and turned my attention to the easy stuff. I cleaned the carbs and tweaked the settings. I lubed up the steering cable. I tightened some fittings around the 2 livewell system. We used the boat a few more times, each time I would tweak a little more. By the end of summer, I had decided it was a keeper so I dropped another $1000 on electronics and I rewired behind the helm and at the bow. I never did get to the bottom of my idle issue, though. In August, I had stripped down most of the engine to try and find the issue, and that is where my progress stopped.

I haven't touched the boat since then. It has sat in the garage, collecting dust and cobwebs. With my busy work schedule, my kids now involved in 2 sports each, and my wife working, I didn't think I would ever have time to fix or even use the boat. I contemplated just ditching the thing for what I have in it, but recently thought better of it and have decided to move on with it. This is where I am going to begin my journey with all of my fellow iBoaters. As mentioned, I don't know just how must restoring I will do or how often I will be able to do it, but I do promise it will be something.

Because I know iBoaters like pictures, here are the only ones I have of the boat.