Technically, I should have had the cap back on yesterday. However, a few things came up that I wasn't expecting. First, all the resin on the backside of the splashwell needed to come off so that it would sit on the new transom right. So away I went with the grinder. Then, I just couldn't get it to sit back on the hull like it was supposed to. Nothing I did was hanging it up, but from what it looked like I suspect that the new transom and foam pulled on the hull just a little bit to cause a little bit of tightness. I gave up on the night as I started to get frustrated.

I pondered my options throughout the day. First, I thought about cutting off a half inch or so at each cut by the hatch. This way I would have some wiggle room with the cap... but it also meant I would have some gaps to fill and glass. Next, I thought about using some steel and screws to act as a bridge and pull the pieces flush with each other. But then I thought about just riveting the cap back on and going from there. Well, that seemed to do the trick. As I started to pop in the rivets, the hull and cap started to come together where it needed to be. By the last few rivets, it was off by a millimeter or two, which is well within the tolerance I wanted. Up at the joint between the rear cap I cut off and the rest of the cap, I have a barely noticeable offset. I can grind this down smooth while I am preparing to glass the two pieces together and it will no longer be an issue.

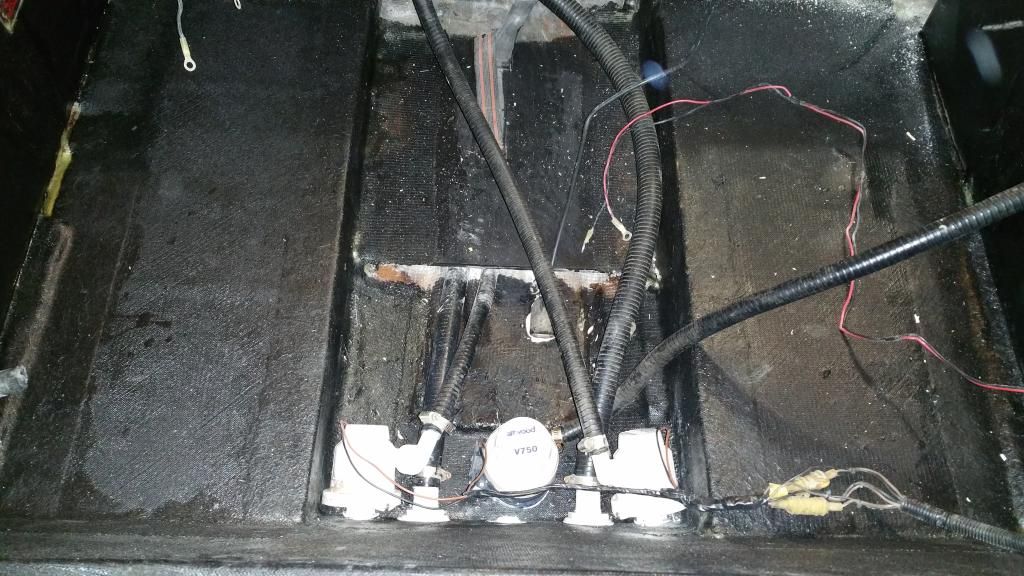

Oh, I forgot to mention that I got all the pumps and thru-hull fitting in before messing with the cap. All the wires and cables are ran where they need to be. I opted not to mess with anymore bedliner since it doesn't really matter. Everything was coated in 5200 on both sides to ensure a good water tight seal. For the garboard drain, I used some 3/4" PVC on the inside to mate up with the end of the garboard and left it protruding from the inside by a few millimeters. The PVC and garboard were also 5200'd in place. Everything should be good to go.

I stopped at the point of finishing up the rivets. This weekend I will officially glass the two pieces back together and will be ready to move on the next stage (sanding/filling holes/getting ready for paint). It's a trivial thing to be upset about, but I hate that my pretty new bilge has been tainted with grinding dust from the top cap. I vacuumed it out and gave it a wipe down with acetone, but didn't bother with getting it sparkling clean again (especially since it will see water soon). First world problems, I suppose.

Oh, and all the wiring will be cleaned up and hung closer to the end of the project. I'm not going to mess with it until it's all installed in its final location.

After the pumps and such were installed. A little bit of dust contamination already.

Pump on the right is at an angle because the thru-hull drill hole was just a bit too close to the stringer. I think it was like this originally as well. Shouldn't be an issue, it's all coated with 5200.

Cap is back on and riveted in place. I dare you to spot the offset at the cut (no close up, so you can't really see it).

From the rear. Still can't see the offset, but it's there.

And just an inside shot. Dust contamination, but it will get washed out soon enough.