Bt Doctur

Supreme Mariner

- Joined

- Aug 29, 2004

- Messages

- 19,480

More of a protective guide for the cable . dosent seal anything. goes into the rear of the housing. The piece of wire is the safety wire to hold the allen screw in the shift slide

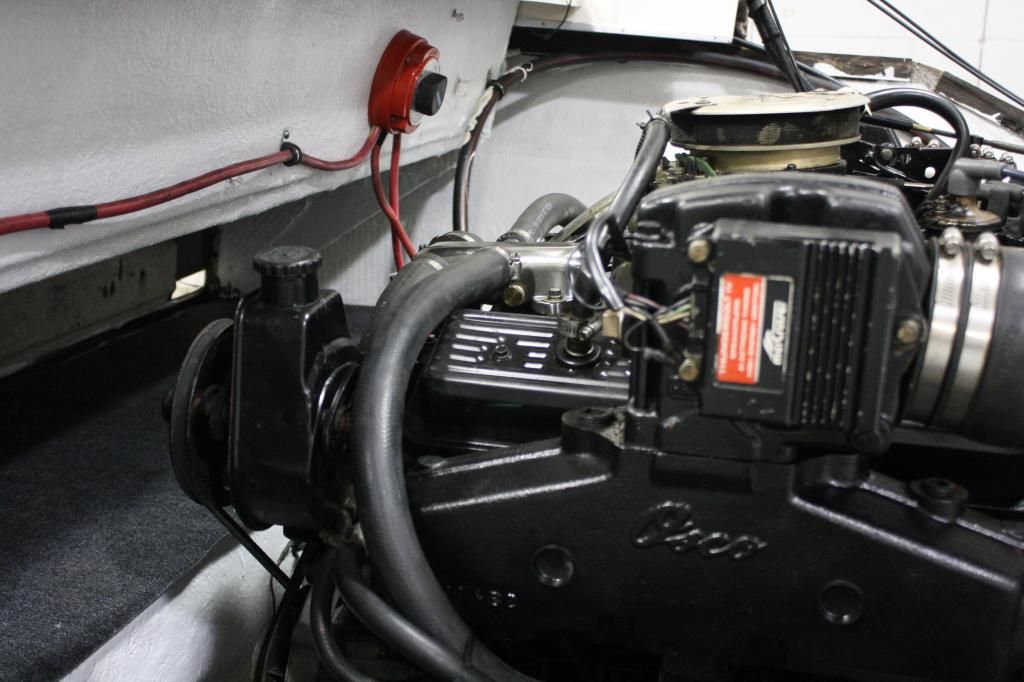

Review post #91. the Aluminum bracket looks nice but can raise the engine up. You may have to remove the front mounts completely and lower the engine to test fit the alignment.

Review post #91. the Aluminum bracket looks nice but can raise the engine up. You may have to remove the front mounts completely and lower the engine to test fit the alignment.

Last edited: