Alright all you carb die-hards, get your "I told you so's" ready. I blew the engine in my boat yesterday. 100% was my arrogance / indifference to multiple small warning signs that I ignored, and about that I'm pretty bummed. But...I've slept on it and I'm going to try like hell to have it back up and running for the July 4th weekend at my brother's lake house. Here's what happened:

Yesterday morning on muffs it was running OK on the initial tune. It warmed up to 160F and held and AFR seemed to be staying in the 11's, so pretty rich, but I figured once learning kicked in, it would start adjusting the tables. Then, all of a sudden the touch-screen was showing "No Data!" for all sensors (red flag #1). The Holley can run fine without the touch-screen connected, but I can't monitor the AFR without it. I switched from the touch screen to my computer and could not connect. Then after a while, the touch-screen started working again. Ultimately I think there is something going on with the wiring harness on the Sniper, and plan to call Holley tomorrow.

Anyhow, we loaded up and went to the river. At the ramp the touch-screen connected when I keyed on, but while cranking it went back to "No Data!" (red flag #2). It also didn't start right up on the first hit like it had in the past on the Holley (red flag #3) - it acted flooded, but I got it started, off the trailer, and tied to the dock. After getting the family loaded, it started right up on the first hit like I expected, then we were off. This time the touch-screen never came back from "No Data!", but I figured we would take a short ride up-river anyhow (completely ignoring red flags). It was running OK, so I decided to open it up. I could tell at WOT it was slightly down on power (red flag #4), so I decided to throttle back some. Shortly after that a loud bang and I could hear that we were losing compression from a cylinder. Oil pressure and water temp never faltered, so we limped it back to the dock, put it on the trailer, and went home.

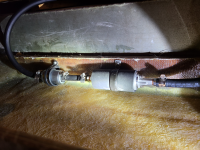

The loud bang was the guts of #2 spark plug departing the engine and hitting the side of the hull. It was hot enough to leave a mark on the carpet on the side-wall, and to leave a burn spot in the bottom of my bilge. This is where the chuffing / loss-of-compression sound was coming from. I pulled the remaining plugs and #7 was also broken and about to come out as well. No broken/beaten ground straps, and the other 6 plugs looked on the rich side of things but OK. Compression test showed #7 is a dead hole (0 psi) but the remaining cylinders are still good. Based on what happened, I'm assuming that under load the engine went lean. With no touch-screen, I could not monitor AFR and get out of it in time (what an idiot).

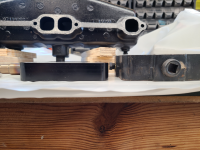

That's as far as I made it yesterday. I'm taking tomorrow off work to pull the drive and engine out of the boat and then pull the heads off. Even though all 4 cylinders on the even side had good compression, I'm still going to pull both heads to make sure all is well...especially since the #2 plug failed catastrophically. Best case would be a burnt valve or something that the bottom end can stay together for. Worst case would be a fire slotted block, hole in the piston, or something along those lines.

The broken plugs:

The mark on the inside of the hull where the #2 plug hit:

The burn mark in the bilge where the #2 plug came to rest:

![20220531_195133[1].png 20220531_195133[1].png](https://forums.iboats.com/data/attachments/361/361853-10d3f64d3acb3e72a2256ed95315edf9.jpg)