Re: 1985 Conroy X-19 I/O Transom Restoration

Thanks for the compliments Rick!

Wood, that makes perfect sense, but I wouldn't have thought of it... thanks. I did put 2" screws around the edges and between the clamps in the middle to squeeze things together. I'm confident everything is bonded solid. Funny you mentioned the Whizz rollers because I picked up a pack of them this evening. I will follow your glassing procedure exactly and everything should turn out nicely.

I wanted to bring up the fiberglass and temperature topic again. I've seen everywhere that 60 degrees F is the cutoff temperature for glassing, but I was reading through the Oops! project and noticed he was intentionally trying to keep his garage at 50 degrees. I'm just curious what the risks are because I'm restricted to working outside on my boat and with cooler temperatures approaching I'm getting a bit stressed with wondering how I'm going to get all of this done before it's too cold (end of October I'm guessing). Even now, the temperatures are getting in the mid to upper 50's overnight.

Is it going to be okay to fiberglass mid-day when temperatures are in the 60-70 range even though temperatures may fall into the 50's overnight? If it comes down to it, is it okay to fiberglass in 50-60 degrees with possibly 40's overnight? What's the scoop? I little pressure is good to keep me motivated, but I don't want to get into rushing things and making mistakes. If it has to wait until spring then so be it. I do have the engine and stern drive to work on

FYI, some advice based on my experience:

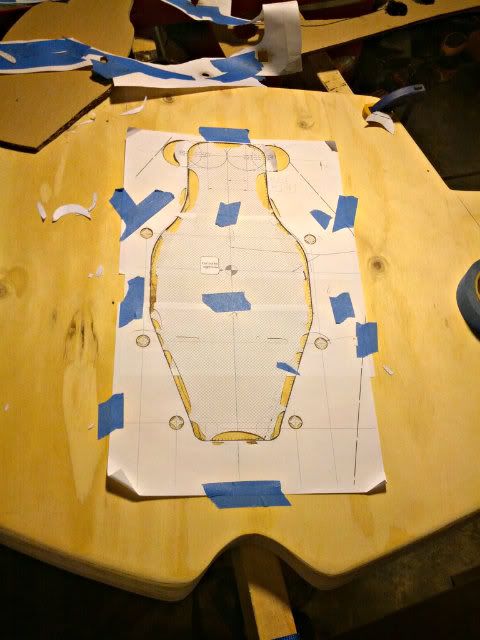

The Arauco 7 layer plywood from Home Depot was solid all the way through and I was very pleased with it. Nothing compares for the price (that was readily available for me anyway). I highly recommend it for transoms... assuming it's entirely covered with fiberglass.

The PL adhesive starts to cure fairly quick and gets a thick consistency so you want to get things clamped pretty quick to get it to spread nicely. It's not like standard wood glue. Those blue plastic quick-grip clamps I used just didn't have the power to pull all three sheets together properly, but it was what I had to work with (they certainly helped). You definitely want to used metal screw clamps, the threaded rod and 2x4 clamps, and standard drywall screws all around to pull it down tight.

Also, I've been meaning to share pictures of my homemade gantry I built for $90 (including the 1 ton chain hoist). I used two 2x6s screwed together for the main beam which may have been overkill for my Mercruiser 140 (I read it weighs around 350 lbs), but better safe than sorry (or injured).

Hopefully fiberglassing the transom tomorrow evening!

Regards

Sorry to add more to this post... it's already turned into a short story. I was reading through Rick-101's thread and he mentioned drilling his transom holes (for the through bolts) oversized to allow for extra peanut butter in there (before mating the transom to the hull of course). That seems like a good idea to me since that's a likely area for water penetration over the years. I was also applying that same logic to the keyhole.

What about cutting the keyhole out oversize and then putting in a layer of CSM or even 1708 along the edge? Thoughts?