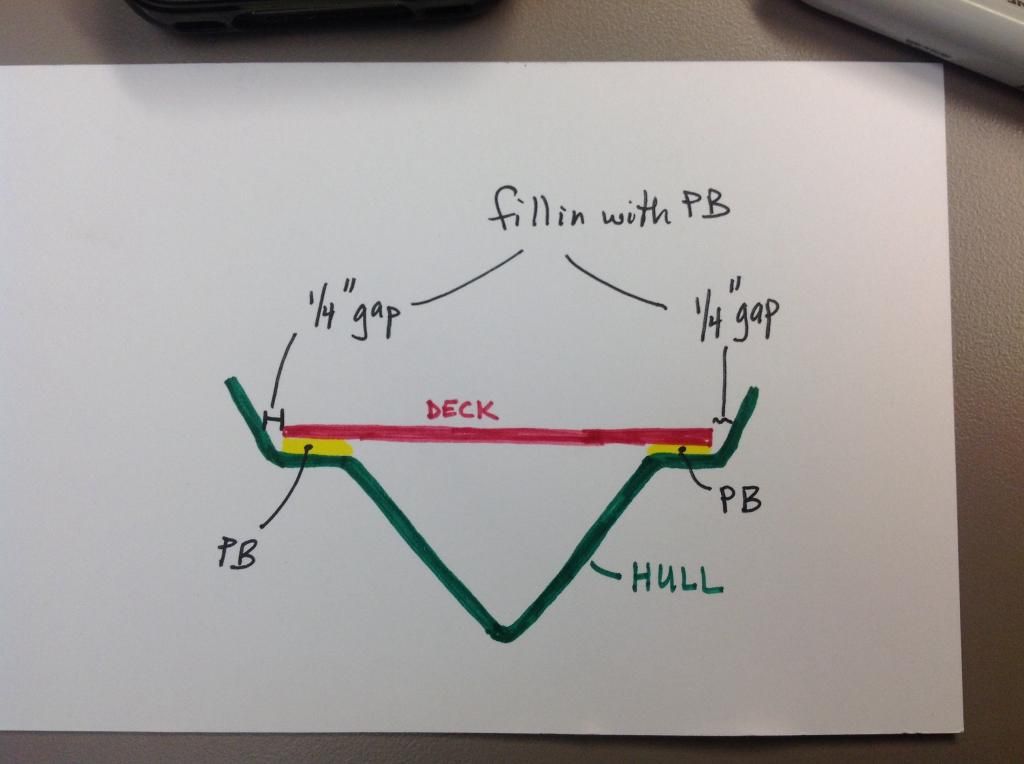

Not sure I completely understand your question Pita. If you are talking about the top of the stringer wood to the bottom of the deck wood figure about .040" per layer of CSM so one layer to cap and one on the bottom of the deck is .080, just over 1/16" (figure .050" for 1708 if you cap with that - like it matters!). So many ways to skin this cat. Did you see how Nurseman setup "stands" fore and aft to hold his stringers in place? I used cardboard to get the hull shape (foam board works good too). Taped a sharpie to a stick at a 90 and slid it along the hull to scribe the shape on the cardboard (friscoboater has a video of it). Then I used a straight edge (strings) at the front and back of the stringer across the hull at the height of the bottom of the deck and recorded the height of the stringer at each end. Cut the hull shape on the cardboard, trace onto wood, measure up at each end the stringer height minus the 1/4" and 1/16, connect the dots and cut the stringer top. Did the same for the bulkheads but used the installed stringers to set the height. My main goal was to avoid trying to cut the stringer tops once installed and it worked. I hope that made some sense.