Rickmerrill

Senior Chief Petty Officer

- Joined

- Mar 13, 2014

- Messages

- 686

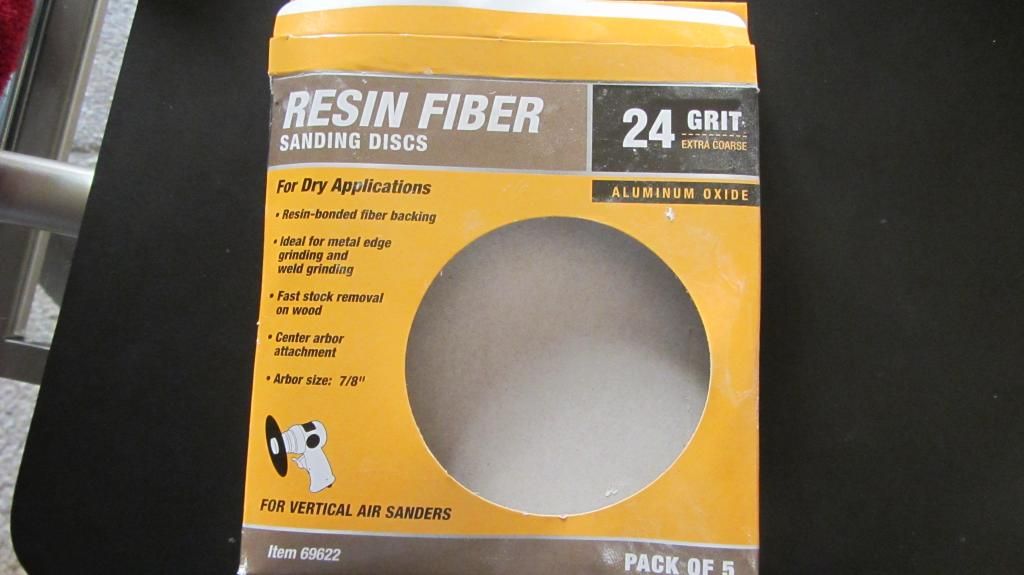

Just need to "rough and scuff" s

o worst case you may need to do some hand sanding with 60 grit (I've used the multitool to "sand" a little) but I'll wait for the pictures. It's called a load leveler or engine leveler. Glad to see you're open to the idea of pulling it should it become necessary.

o worst case you may need to do some hand sanding with 60 grit (I've used the multitool to "sand" a little) but I'll wait for the pictures. It's called a load leveler or engine leveler. Glad to see you're open to the idea of pulling it should it become necessary.

Last edited: