Re: 1982 Glastron Hpv165 bass boat restoration.

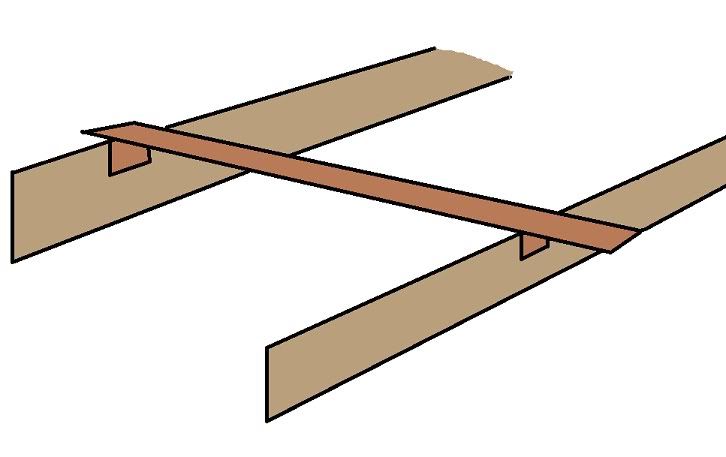

Hey woodonglass. Thanks for the workup drawing on the stringer jig. That's exactly what I'm talking about when I mentioned "other ideas I haven't thought of yet". That drawing solved a big issue for me. What a great tool!

As for the measurments on the floor, this is what I did...I hope you noticed my pictures of how I cross braced the hull before I cut the floor up. The reason I say that is because I used the cross braces themselves to make the floor hieght measurments. I marked them each in three spots, one above the starboard most side of the floor, one in the center above the the keel and one above the port most side of the floor.

From there I measured from the top of the board on each of the marked spots down to the floor and wrote the measurment on the board itself. The measurment above the open keel area was for the purpose of checking for hull shift. The measurments did vary a small amount even before I cut the floor out, but this could also be credited to the boards not being straight as well.

Now with the use of the stringer jig you drew up for me, I should be able to make three of them and place them directly beneath the brace boards, line the stringers up according to their cross measurments, shim them up somehow to the correct height and backfill underneath them with whatever you guys tell me I'm supposed to use to secure the stringers and cross braces to the hull with. Is this the correct method?

I would actually prefer your method Jc, in referance to cutting the stringers to match the exact contour of the hull. That just seems to me like the best method to me for satisfying my OCD.:laugh: However, I don't trust myself enough to cut the bevels into the bottom of the stringers when the wood, resin and effort to make them is so timely, expensive and could be so quickly ruined. Also, cutting the angle of the bevel to fit the hull would be very difficult in the case of this particular boat. It changes angles frequently and they would each have to be match fitted with a router or something to fit perfectly. I really want it done that way but I just don't think I would get good results.

The changing angle may very well be the exact reason why the existing stringers also weren't match fitted. Who knows? Would the manufacturer cut them flat like that? I do have to say that there is no way I will be leaving the gaps underneath of the stringers that were there when I took them out. That just makes no sense to me and seems like the job was rushed or done by someone who is lazy. And like I mentioned before, there was literally standing water underneath in the gaps.

Good to hear things are alright for ya GT1M. I hope you get the wiring figured out. Thanks for the pics of the lay-up process you used. I have to say I'm a bit confused as to your method.

I noticed that you had your stringers installed in the first pic with one smaller layer of 1708 overlay running the length of the stringers. Then in the next pic you had what looked like a larger layer completely covering all three stringers with again another smaller layer over the the stringers on top of that.

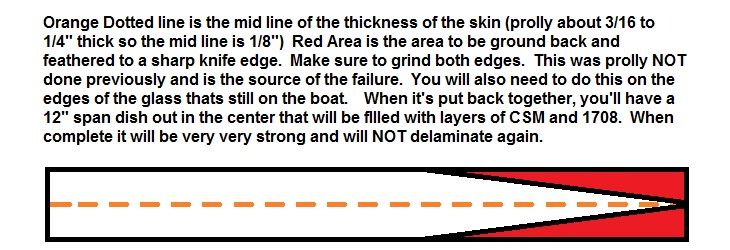

I was under the impression from a few of the other threads that the layers should be layed over the stringers as one layer on each side of the stringer to cover the sides down to the hull, one layer covering the complete stringer and overlapping the first side layers, then once more again overlapping even further over the first two. Is that the way you did it, but I just can't see in the pic because it's covered? Or does each type of hull and stringer require a different method?

Please beleive that I'm not criticizing your work, I'm just as we have mentioned "trying to figure out the best method". I also beleive that there can also be more than one way to acheive the proper result.

I also have a few more questions that I have thought up...

I can understand for sure the purpose for building the transom and sole out of some type of marine grade plywood but, as for the stringers and cross braces, is it really necessary to use such a high grade of plywood to build them with when they are going to be completely wiped down and soaked in resin and sealed within resin soaked layers of glass and covered in foam, bilge paint and a glassed in floor?

As for that question, yes I am trying to find ways to save a bit of money. However, I will also go the other way with it if it's completely necessary. I do want to do a good job.

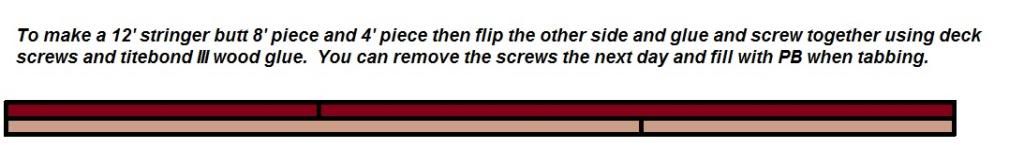

As for building the stringers. If made of plywood rather than long complete strips of hardwood...plywood will come in the usual 4x8 sheets. If I remember my measurments correctly, my stringers will need to be about 14 feet long. I will obviously need to cut them out of two sheets of plywood. What is the best method for conjoining two lengths of stringer together to make the one required peice. Would a dovetail connection work? I hope I'm using the right terminology when I say "dovetail" for explaining what I mean. I hope that makes sense to you guys?

Or is there a better way? This is kind of why I would also like to use single lengths of hardwood for the stringers and cross braces. I have seen them for sale in the building and home supply stores too. That is also what the existing stringers are made of, they just weren't sealed and treated properly.

Has anyone used the single peice hardwood method rather than the plywood method? If so, how was your experience with it, and how is it holding up for you?

Thanks again to everyone and I look forward to hearing from you.