I got the Wagner seal kits in the mail,

There are three helm pumps in the Wagner 700 series line-up, the 701, the 702, and the very rare 703, which was built for the military. My lower helm pump is a 703, and I'm not sure what my upper pump is (no visible numbers on it). The difference between the 701 and 702 is a mystery to me, although the Wagner tech asked me weather the shafts are aluminum or brass. Both my pumps have brass shafts. The way the 703 differs is it pumps more oil per turn of the wheel, reducing the number of turns from stop to stop. It achieves this by having more of a slope to the bearing seat which is machined into the housing. If my upper pump isn't a 703 I will notice a slightly different number of stop to stop turns, I'll check this out after reassembly. Maybe that's the difference between the 701 and 702? :noidea:. All the 700 series pumps use the same seal kit.

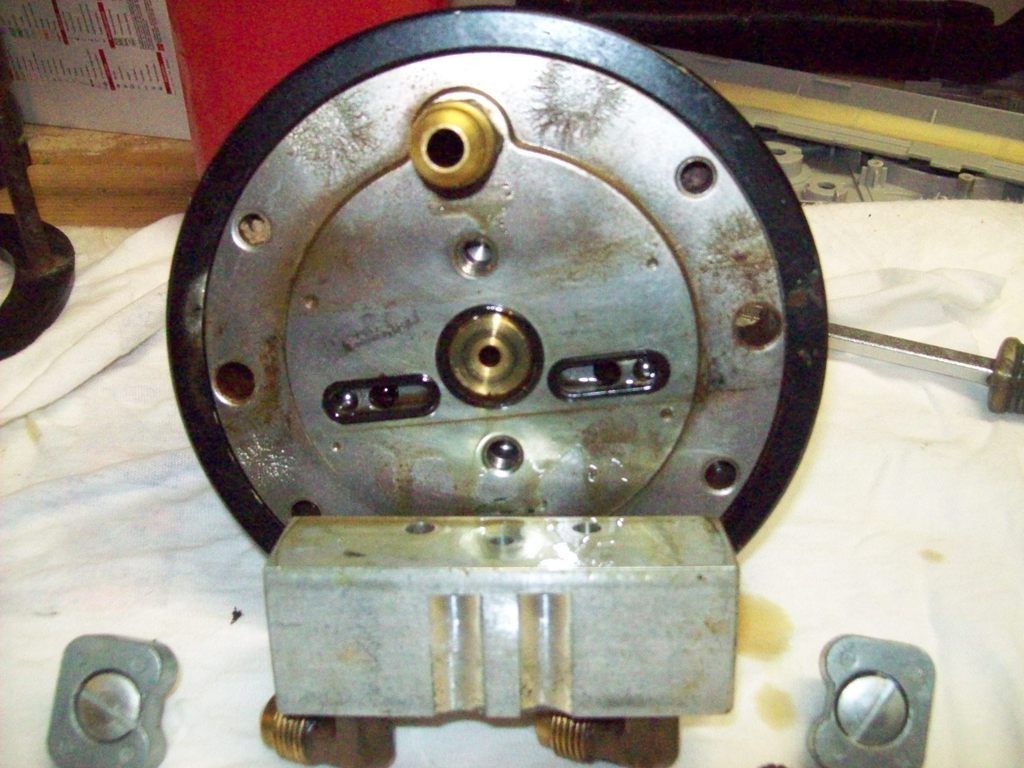

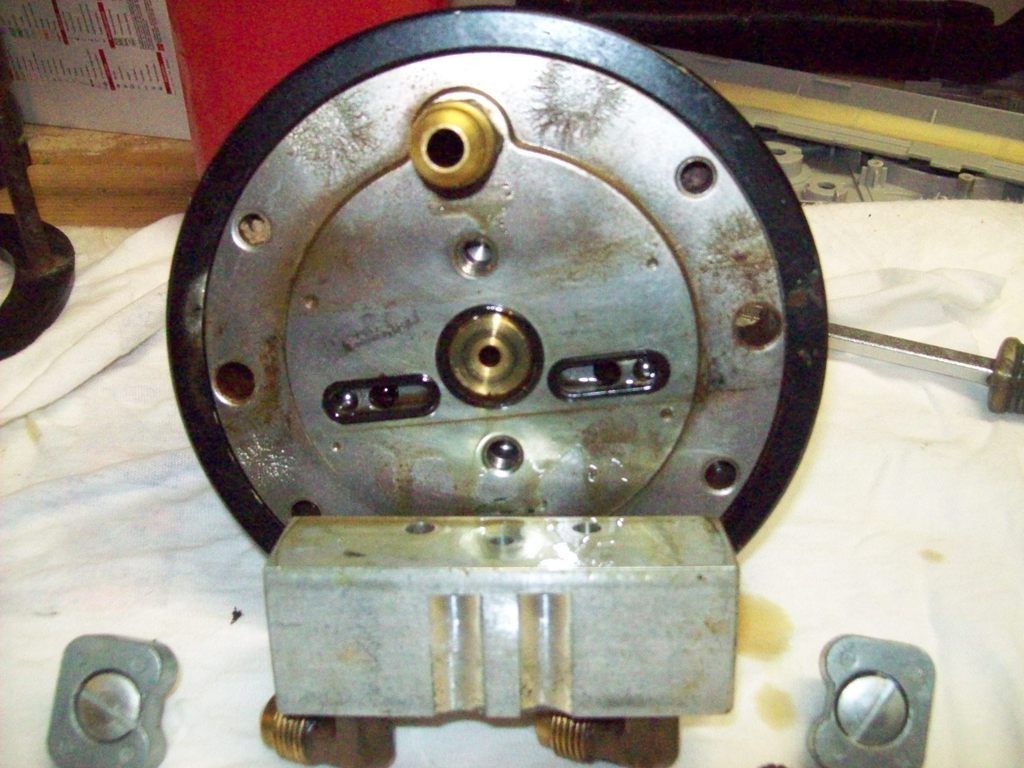

I took lots of pictures which really helped during reassembly. Here's the underside,

And the underside with the lockvalve removed. The clamp bars and cap screws are all aluminum, as is the lockvalve body. You can see three O-rings here, two little check balls, and the end of the shaft,

O-rings and check balls removed,

Here's what's in each end of the lockvalve; the end insert (their terminology) with o-ring, a spring and check ball,

I removed the end nut,

And the backplate,

This shot shows the rotor removed with the pistons in place and the bearing with bearing cage resting on top,

Inside the housing you can see how the bearing seat is machined at an angle which causes the bearings to push on subsequent pistons as the wheel is turned, which of course pushes oil through the system for steering,

You can see the woodruff key and snap ring on the shaft,

the bearing set is four pieces,

This is what makes up the piston assembly; the piston, spring, and piston insert,

I removed the piston assemblies, cleaned them, and re-inserted them in their original place in the rotor one at a time as advised by the tech at Wagner. I cleaned everything with solvent before putting it all back together. I used Lubriplate 101 on the seals and O-rings and sprayed form-a-gasket on one side of the body gasket to hold it in place. The last thing I installed was the shaft seal at the front (steering wheel) end of the housing using an impact socket of the right size and a hammer to tap it in straight and even. I got both pumps done and ready to go (fingers crossed).

. I do it frequently:facepalm:

. I do it frequently:facepalm:

.........