Moserkr

Chief Officer + Starmada Splash Of The Year 2021

- Joined

- Nov 23, 2020

- Messages

- 883

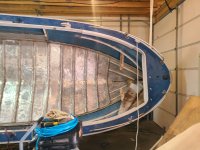

Just a thought for the knee brace vs welding new wings. Im not the only one to have done it this way but finding them in poor shape is pretty common. Guaranteed this is stronger than it was when originally manufactured too. Edit: Made all the rivets 1/4” instead of 3/16” where its attached to the hull to help fill holes and add strength.