Thank you everyone for the valuable input. Unfortunately I didn’t realize my thread had a second page and didn’t see any responses after my last post, so I ended up buying 2 gallons of Hurculiner. After seeing the posts I tried to return it, but apparently flammable substance can’t be returned.

I am currently leaning towards the softsand route with gelcoat as that seems to be a similar route concerning my original thought of using Herculiner. I am having considerable difficulty choking down the fact I just flushed 200 bucks down the toilet unless I can think of a useful return on investment for it. My curiosity is peaked as to why there is so much hate for bedliners, Herculiner in particular, as all bedliners are not the same. As I can’t return it, I used a scrap piece of marine plywood and some 1708 to see what it would look like. I’ll give it a good 5 days to cure before I start beating the holy hell out of it for fun and to evaluate possible alternate uses.

Regarding current progress with the stringer layups, as I understand my ignorance with fiberglass shines, I didn’t realize why I was having such a hard time saturating my first batch of 1708 during the layups. It wasn’t until I had got into my second batch of 1708 that I noticed how much less resin was required to saturate it, and how it was much easier to work with. Then I took a closer look, and noticed the doubles stitching. I would like to think that the stitching used is fiberglass, but it is more than likely not and likely not adding any structural benefit. After doing layups with the correctly manufactured 1708, I am fairly certain I have wasted about 3 gallons of resin working with the double stitched, ouch more money down the toilet with no conceivable benefit.

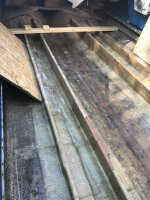

There are a few pictures of what is now my Frankenstein SNAFU project. These are from about a week ago, and have since added 4 watertight bullheads (as opposed to the original 1 at the bilge), and just finished all of the bulkhead and stringer layups. I was on the fence about an open bilge throughout the boat, or watertight below deck and ended up committing to water tight with compartments to minimize the eventual water infiltration damage.

That’s what I have so far, but I would like to hear more about why bedliner is so despised, since I’m stuck with it, and I would like better digest the monetary loss of not using it.

As a side note, if any moderator could update my title to be more accurate, my boat is a 770, I used wildcards ** as I didn’t know for sure which model it was, not on the title, not on the registration. While staring off into space looking at my boat, I noticed a small emblem on the side, haha.