HypnoCraft

Petty Officer 3rd Class

- Joined

- Aug 30, 2018

- Messages

- 94

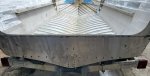

Little update from today. I preped all the patches and got 8 out of the 11 small ones put on. other than that there is the large bilge area patch that needs to be done still and 2 spray rail patches.

I cut them out, rounded all the corners, and filleted the edges to at least lower drag a little bit. then I put them in place, drilled one hole, bolted it into place and drilled the rest of the holes, then I took the patch off, ground the boats skin and the patch with a stripping wheel, applied Sikaflex, and rebolted it all. Once its cured and I have a partner all of the bolts will be replaced with solid rivets.

Have a good long weekend everyone!

I cut them out, rounded all the corners, and filleted the edges to at least lower drag a little bit. then I put them in place, drilled one hole, bolted it into place and drilled the rest of the holes, then I took the patch off, ground the boats skin and the patch with a stripping wheel, applied Sikaflex, and rebolted it all. Once its cured and I have a partner all of the bolts will be replaced with solid rivets.

Have a good long weekend everyone!