UConnMRB

Petty Officer 2nd Class

- Joined

- Jul 18, 2014

- Messages

- 119

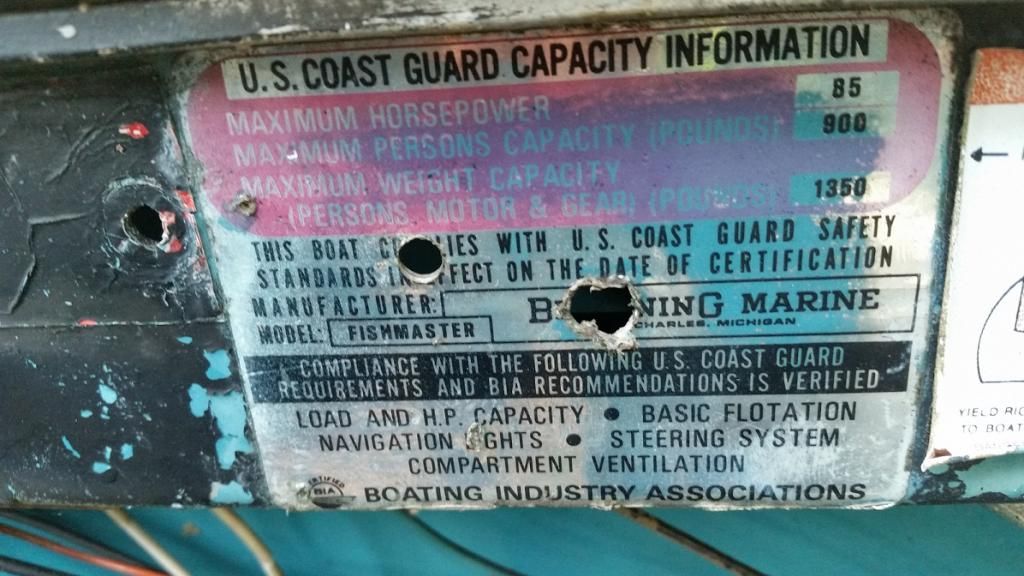

Ok, so here I am the new proud owner of a tin boat. I have no idea what I am doing. That is where I lean on you tin-America. I have zero- I repeat- zero experience in restoring boats. This 1976 Browning Aerocraft Fishmaster was my grandfathers who passed years ago. For about 10 years it has been sitting neglected. I plan on changing that.

Last edited: