Back again!

Some trailer shots:

The trailer is pretty rusty, but that is to be expected for a 1973. The PO had attached wood to the frame, not sure why other than to maybe strengthen the frame?

The wood board in the back has the transom saver mounted on it. I will need to get an extension made for the back so I can mount the transom saver. I do not plan on using the rollers, I will be going to bunks.

Another good shot of the rust.

The main components of the trailer frame ready for sandblasting. I found a great place in Winnipeg for the sandblasting. I dropped my parts off in the morning and they had them done by lunch. The finished product looked great, and the price was reasonable.

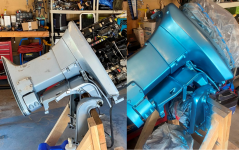

Self-etching primer coats complete!

I decided to go with black vice white or blue. The main reason for this is that I may yet apply Linex to parts of the trailer where it takes a fair amount of gravel strikes. I seem to remember Candutch doing this to his trailer rebuild.

The finish on the trailer worked out well. I am happy with it. I just finished with the axle and leaf springs. They get the top coat today. Once that is done, I am ready to start putting it back together.

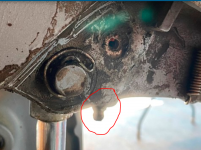

A question for the experts. Is it possible to get bunk brackets that mount to the main frame instead of the cross members? See pic below:

As you can see there are no cross members. I am looking to get Budski's son John to weld some L brackets along the main frame so that I can mount cross members in place. However, it seems to me that the bunks would be quite narrow. Open to thoughts and suggestions on this one...