FIGMO

Petty Officer 1st Class

- Joined

- Jun 18, 2017

- Messages

- 321

Hey SHSU,I got the Attwood Battery boxes with strap. They work like yours, but it had plastic hardware. I was torn on upgrading to SS, but decided I would try what it came with first. Haven't had an issue yet.

As for ventilation, isn't it an open area or you going to seal it?

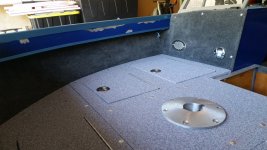

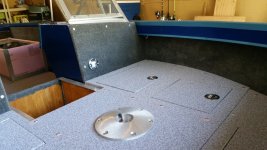

SHSU

This is a rather late reply, sorry about that. I intend on closing off the area under the splash well with a door. I also plan on mounting vents in the door to create some air flow so that gas vapors don't collect under the splash well. As such I need to figure out what would be a good sized vent to allow for good air flow.