Crankerbait

Seaman Apprentice

- Joined

- Nov 5, 2021

- Messages

- 31

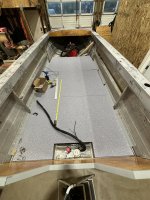

I like it. I was imagining something similar. I want to get them as low as possible but also want to have access to the drain hole at the base of the rib.I made mounting plates from thin sheet aluminum that I mounted the bilge pump bases to. I then riveted the plates to the rear most rib. I attached the pic that shows these best.