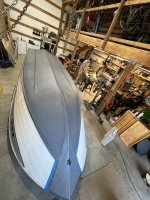

More progress, we got the transom skin on, most of the interior hull cleaned up and made a new Z channel for the base of the transom. The old Z channel was cracked and corroded. We ended up using 1 1/2”x 1/8” angled, T6 aluminum. We cut two lengths and riveted them together in opposing directions to recreate the Z channel. The bottom section of the transom feels like it will be solid. I still feel we will need additional support where the 115 motor mounts at the top of the transom. Thoughts on this? We plan to repair and reuse the original splash well, but that only seems to provide additional support about half way between the bottom and top of the transom. Will that be sufficient? I thought about using a piece of aluminum C-channel on the inside of the transoms, having the upper mounting bolts of the motor going through the C-channel to hold it the transom. The C-channel would be horizontal across the transom at the level of the top bolts. Is that unnecessary? Is it possible to make the transom too rigid which would put too much stress on the seems where the sides and transoms meet?