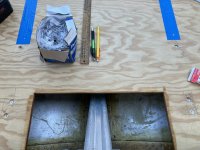

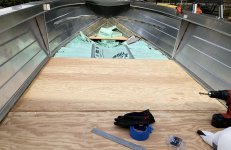

Put the eight screws through the inside bottom transom angle and into the transom. Used 5200 on the threads as a sealant. Then I removed the two screws, one on each side of the angled vertical transom support, because I wasn’t sure if a screw went there or a bolt went through the lower corner holes of the outside plywood motor plate and through the transom and the lower aluminum angle piece. Darn if I can find a photo among all those that I took that shows that spot/hardware. Anyone care to look at this area on your boat and see if that location has a screw or bolt attachment? Thanks!

Safe boating,

Joe

Safe boating,

Joe