Moserkr

Chief Officer + Starmada Splash Of The Year 2021

- Joined

- Nov 23, 2020

- Messages

- 883

Forgot to press send when I wrote this earlier.

To (hopefully) simplify what I wrote lol...

Scuff AL with nylon brush or sandpaper

Wipe with 50/50 vinegar water mix

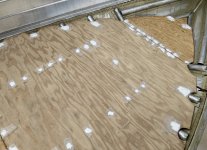

Apply spray can self etching primer within a day (this is a very light coat, AL still visible)

Apply primer with fine roller brush within a day or two

Apply topside paint within a day or 2 (check specific primer directions to be sure)

Apply second/third topside paint coating (follow directions)

To answer your latest post, I think the idea of leaving the hull below the waterline as bare aluminum is great. Paint on the bottom just gets scuffed up and if topside paint is left underwater too long, can permeate and peel. I would have left mine bare but did not have the option. A white boat with blue trim will look very sharp indeed. I painted my outer hull first (turtled though). Once I flipped it back over, I painted the interior. My splashwell and consoles were painted so they were installed prior to painting the interior.

You could paint the interior or exterior first, whichever you want, since you do not plan on turtling the boat. I would focus on one or the other, giving yourself time to get it just right! Sounds like you have a great plan in your head!!

To (hopefully) simplify what I wrote lol...

Scuff AL with nylon brush or sandpaper

Wipe with 50/50 vinegar water mix

Apply spray can self etching primer within a day (this is a very light coat, AL still visible)

Apply primer with fine roller brush within a day or two

Apply topside paint within a day or 2 (check specific primer directions to be sure)

Apply second/third topside paint coating (follow directions)

To answer your latest post, I think the idea of leaving the hull below the waterline as bare aluminum is great. Paint on the bottom just gets scuffed up and if topside paint is left underwater too long, can permeate and peel. I would have left mine bare but did not have the option. A white boat with blue trim will look very sharp indeed. I painted my outer hull first (turtled though). Once I flipped it back over, I painted the interior. My splashwell and consoles were painted so they were installed prior to painting the interior.

You could paint the interior or exterior first, whichever you want, since you do not plan on turtling the boat. I would focus on one or the other, giving yourself time to get it just right! Sounds like you have a great plan in your head!!