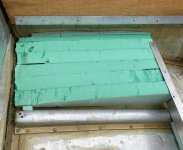

The Admiral and I did a bit of shopping for boat items today. Purchased a new dolly jack for the trailer tongue, a bottle jack, and then spent some time looking for aluminum pop rivets that have a long enough grip to attach the new marine plywood to the aluminum structure. The local fastener businesses around here have a minimum $50 retail purchase in effect for walk in customers but it didn’t matter because all they had was 1/2” grip rivets in stock and didn’t know how long it would take to get an order in. So we kept looking and finally found the 3/16 diameter x 5/8” grip aluminum rivets that we were seeking…at a small hardware store I had almost forgotten about. Purchased three packs of the rivets and headed for home. I checked out the new rivet length using a piece of the marine plywood, same thickness as the new flooring, and found it to be a good fit. In one of the photos you can see the pencil mark made underneath the flooring aluminum and the extra length that can allow a good rivet draw. And onward we go!

Safe boating,

Joe

Safe boating,

Joe