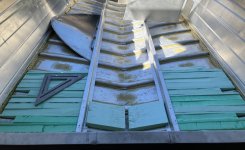

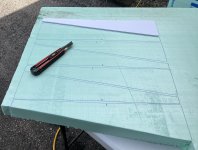

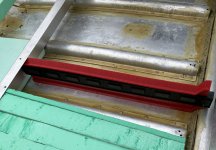

Took the opportunity this morning to try out the new contour gauge and I am pleased to find that the tool worked out fine. Doesn’t have a locking device to keep the numerous contour pins in place when the gauge is moved, however, I just pushed the pins together by pressing in on one end of the gauge and that works fine when transferring the contour pattern. I believe that this tool will pay for itself in time saved while drawing new floatation foam patterns. It started to rain again while we were with the boat so we decided to wait awhile for it to dry up. We presently have 93% humidity and misty fog…and it is warm outside. Feels better in the house with the air conditioning on.  Think I will go downstairs to the model room and work on one of my projects.

Think I will go downstairs to the model room and work on one of my projects.

Safe boating,

Joe

Safe boating,

Joe

Attachments

-

46472546-DB95-42DB-A419-0D78178A924F.jpeg1.9 MB · Views: 11

46472546-DB95-42DB-A419-0D78178A924F.jpeg1.9 MB · Views: 11 -

EEBE6463-EDA2-4497-B23B-8F848ACDCB45.jpeg1.5 MB · Views: 11

EEBE6463-EDA2-4497-B23B-8F848ACDCB45.jpeg1.5 MB · Views: 11 -

AC9BB190-7751-4DEC-A73B-7B99433031BF.jpeg1.8 MB · Views: 11

AC9BB190-7751-4DEC-A73B-7B99433031BF.jpeg1.8 MB · Views: 11 -

B7267660-6DDB-416F-8FB2-A52021B2E25A.jpeg2.8 MB · Views: 10

B7267660-6DDB-416F-8FB2-A52021B2E25A.jpeg2.8 MB · Views: 10 -

495F5348-4045-4040-AD87-F9D3529089B6.jpeg2.2 MB · Views: 10

495F5348-4045-4040-AD87-F9D3529089B6.jpeg2.2 MB · Views: 10 -

D251BF61-AD2B-4004-BD9F-9EEB80AF2656.jpeg1.2 MB · Views: 10

D251BF61-AD2B-4004-BD9F-9EEB80AF2656.jpeg1.2 MB · Views: 10