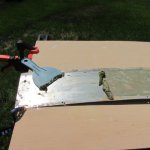

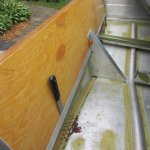

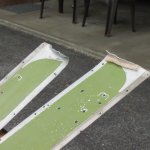

Got the power washer ready to go and am in the process of taking paint off the aluminum parts again! First work on the boat this year that feels like I'm accomplishing something but at least it's a start and step in the right direction. Supposed to be in the upper '60's/low '70's for a week or so and that will be nice outdoor restoration weather. Did have a bit of a laugh, too, as I am using my iPhone for timing the Citristrip applications and was looking at the notification options: one of them was Waves...I had to select THAT one of course. LOL

Safe boating,

Joe

Safe boating,

Joe