zool

Captain

- Joined

- Aug 19, 2012

- Messages

- 3,433

Update:

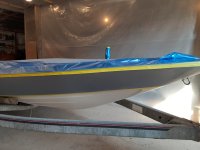

I got the splash well lip all formed and faired now, so there's no more removing the cap in my lifetime. It's epoxied shut.

I also used 3/16 stainless blind rivets to secure the cap around the hull.

It's over 90 degrees here so i'm still waiting to spray, but all I have to do is tape it all off and have at it. I have the 545 primer and 3m glazing putty on hand.

I attacked some inside the hull issues while waiting for a weather window. The plastic trim running around the inner cap was separated on one corner, so i address that with clamps and glue. It will be primed and painted to match the hull.

I got the splash well lip all formed and faired now, so there's no more removing the cap in my lifetime. It's epoxied shut.

I also used 3/16 stainless blind rivets to secure the cap around the hull.

It's over 90 degrees here so i'm still waiting to spray, but all I have to do is tape it all off and have at it. I have the 545 primer and 3m glazing putty on hand.

I attacked some inside the hull issues while waiting for a weather window. The plastic trim running around the inner cap was separated on one corner, so i address that with clamps and glue. It will be primed and painted to match the hull.