Re: 1970's 16 ft Aluminum Mackenzie Runabout Rebuild

Re: 1970's 16 ft Aluminum Mackenzie Runabout Rebuild

Made wee progress tonight. Mixed up a batch of epoxy and applied to one side of bow deck. When dry will flip for the other side.

Starting to think about the drain hole again. Here is a picture of the drain kit pieces.

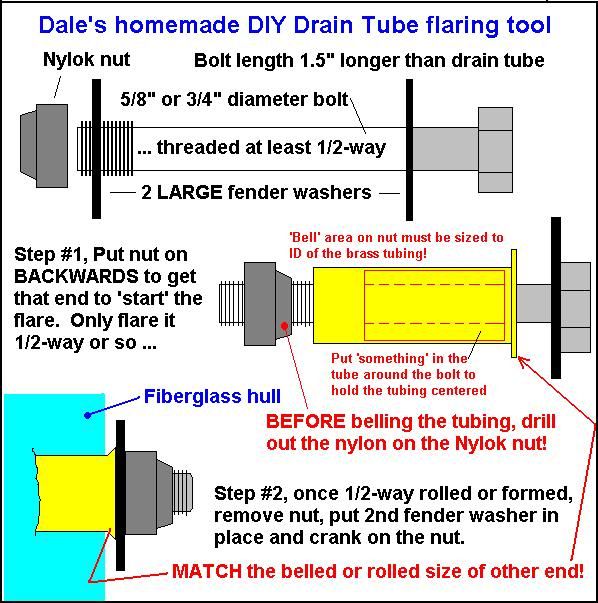

And diagram for installation. I think this kit is supposed to be installed through the transom wood core? Thoughts?

Have a good one eh!

Re: 1970's 16 ft Aluminum Mackenzie Runabout Rebuild

Made wee progress tonight. Mixed up a batch of epoxy and applied to one side of bow deck. When dry will flip for the other side.

Starting to think about the drain hole again. Here is a picture of the drain kit pieces.

And diagram for installation. I think this kit is supposed to be installed through the transom wood core? Thoughts?

Have a good one eh!