Noblo88

Seaman Apprentice

- Joined

- Jul 2, 2014

- Messages

- 39

I can post more pictures of the engine today if that’ll help anyone

As to the kill wires, do you think that could be causing my engine to not fire?

As to the kill wires, do you think that could be causing my engine to not fire?

ok more awake..this a.m.

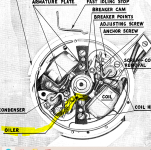

yes 2 blacks going under the FW are kill wires to shut down the engine. they should go to a normally open push STOP switch !

both coils look decent. ..changing condensers may help and a good clean -up on points if you do not want to spend extra $$$ see timing video