Noblo88

Seaman Apprentice

- Joined

- Jul 2, 2014

- Messages

- 39

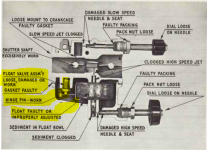

Update. Rechecked the points made sure everything was right about .02 for points and checked continuity and everything was solid, after a few minor adjustments. Still not running, I sprayed a little starter fluid In and it ran for about 3 seconds. I’ve played a lot with the carb Adjustment and I think there’s a possibility that I just need a new carb, everything was cleaned very well and also used an air gun. I’m just not sure what else to check, what do you guys think?