Watermann

Starmada Splash of the Year 2014

- Joined

- Jan 12, 2013

- Messages

- 13,842

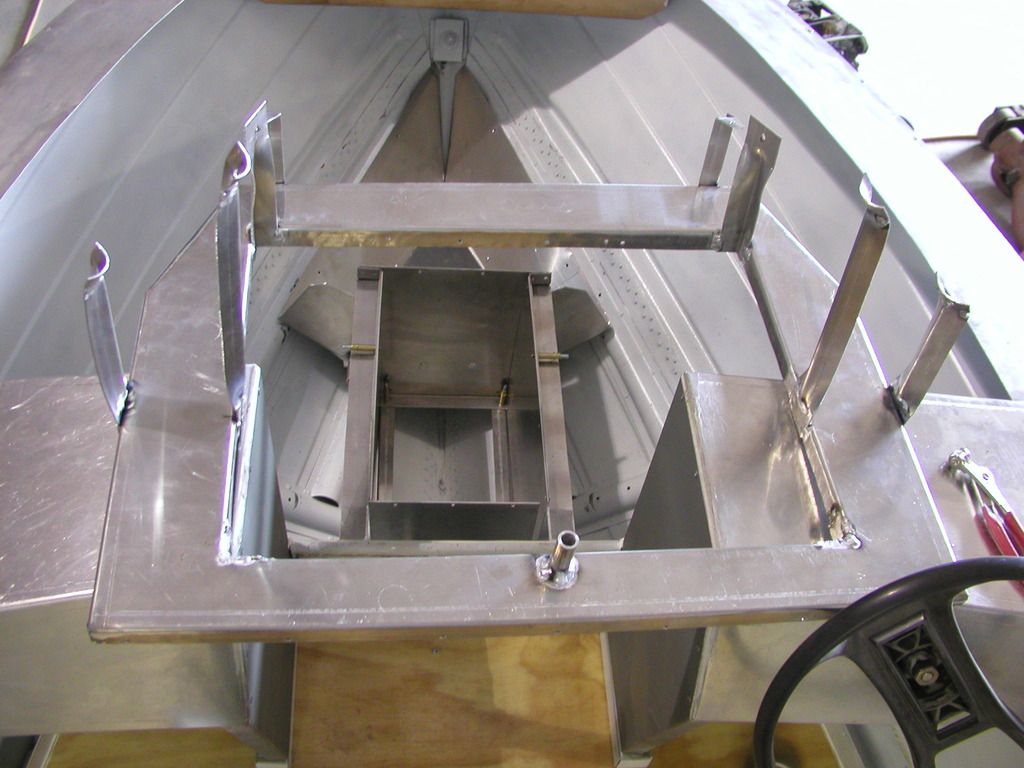

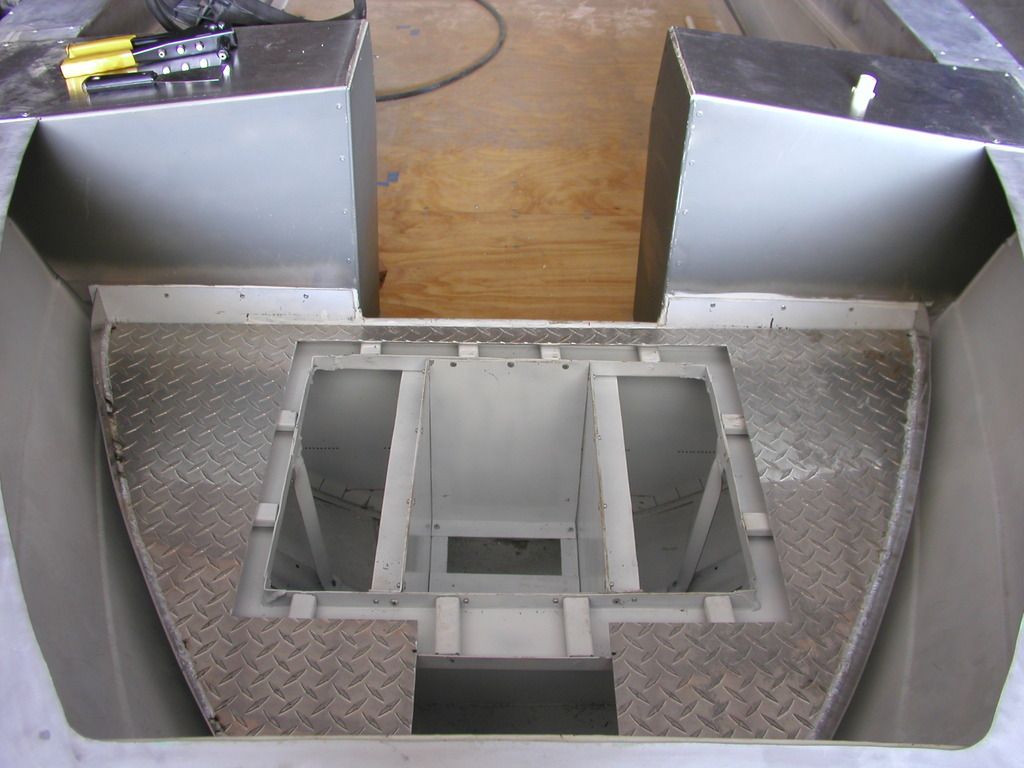

Super nice clean work Ted!

I'm not much for having a fuel tank on either end of the boat, the best place if possible is mid-ship IMO. If you're putting in that fancy 24v elec tm then you'll want the batteries as close to it as possible.

On the motor LU being a jet, it still has the water pipe that drops down the exhaust housing so you can leave the LU off when you do the water pump. After doing the repairs to test run you can fashion up a hose that will go over the water pipe to get water to the motor. Be sure to clamp it to where it doesn't pop off.

I'm not much for having a fuel tank on either end of the boat, the best place if possible is mid-ship IMO. If you're putting in that fancy 24v elec tm then you'll want the batteries as close to it as possible.

On the motor LU being a jet, it still has the water pipe that drops down the exhaust housing so you can leave the LU off when you do the water pump. After doing the repairs to test run you can fashion up a hose that will go over the water pipe to get water to the motor. Be sure to clamp it to where it doesn't pop off.