jakec

Petty Officer 2nd Class

- Joined

- May 23, 2022

- Messages

- 120

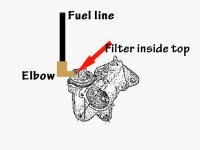

I got this 1977 1150 elpt. It did not start on first attempt when I was at the lake switching trailers. Now I'm looking to get it to start. Compression is all +/- 5psi around 120psi. I have replaced internal harness. Carbs are not rebuilt (not by me at least). Speaking of which can anyone tell me about the cross over tube on the top of each carb? On every youtube video I see they have this passage blocked off?

I set the crank so no. 1 piston is at 5* before TDC. Engine does have an adjustable timing marker but the sticker and flywheel look untouched. I used a screwdriver to confirm TDC, although there seems to be a range of maybe 20* crank rotation with little detectable difference while the piston is transiting TDC.

Anyways, I got no spark at all when twisting the distributor so I removed the plate with the stop screws. I have a strong loud spark now. The spot where the spark actually occurs is retarded from where the stop screw was set (needs to be backed out). Also, the throttle pickup is not yet contacting the throttle arm at the time of spark. It is about to contact, but not close to moving the throttle arm.

I am gona go through the whole link & sync proccess tonight (I have read the FAQ page here on it). I guess I am kinda skeptical to proceed since the two things I just checked are both retarded, it makes me wonder if I'm doing something wrong, and they are already set correctly?

I set the crank so no. 1 piston is at 5* before TDC. Engine does have an adjustable timing marker but the sticker and flywheel look untouched. I used a screwdriver to confirm TDC, although there seems to be a range of maybe 20* crank rotation with little detectable difference while the piston is transiting TDC.

Anyways, I got no spark at all when twisting the distributor so I removed the plate with the stop screws. I have a strong loud spark now. The spot where the spark actually occurs is retarded from where the stop screw was set (needs to be backed out). Also, the throttle pickup is not yet contacting the throttle arm at the time of spark. It is about to contact, but not close to moving the throttle arm.

I am gona go through the whole link & sync proccess tonight (I have read the FAQ page here on it). I guess I am kinda skeptical to proceed since the two things I just checked are both retarded, it makes me wonder if I'm doing something wrong, and they are already set correctly?