mrdjflores

Lieutenant Junior Grade

- Joined

- Apr 1, 2009

- Messages

- 1,169

I'm creating this thread to document how i created my boat seats....

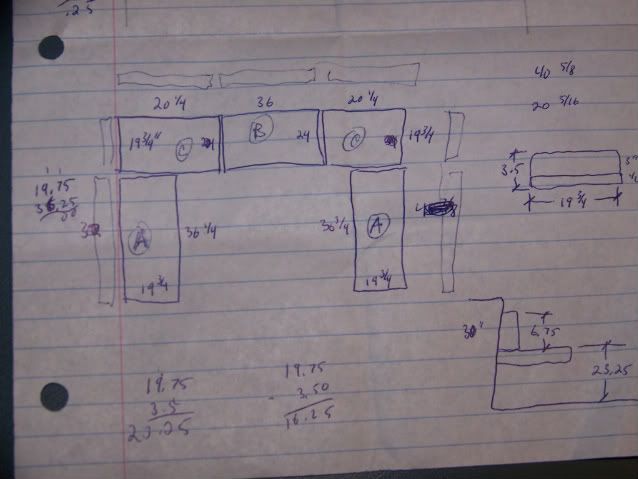

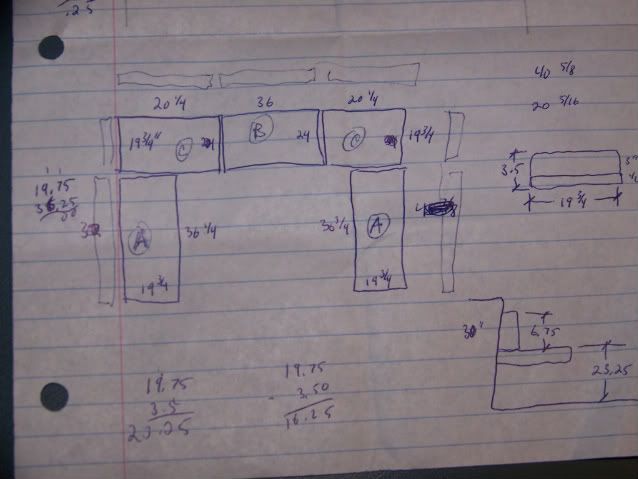

First, i sketched how up i wanted to have my seating arranged in the boat

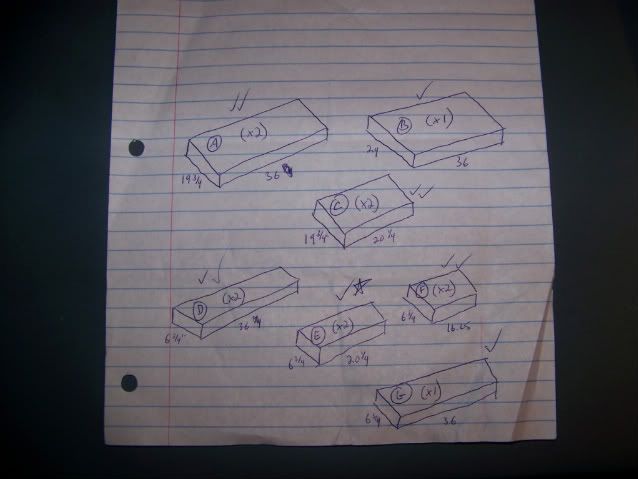

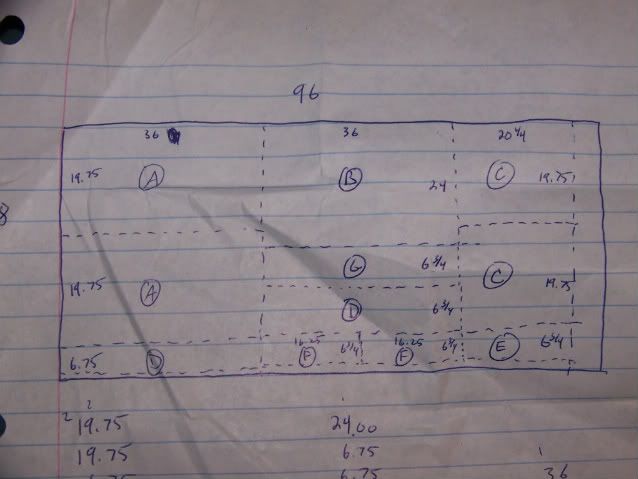

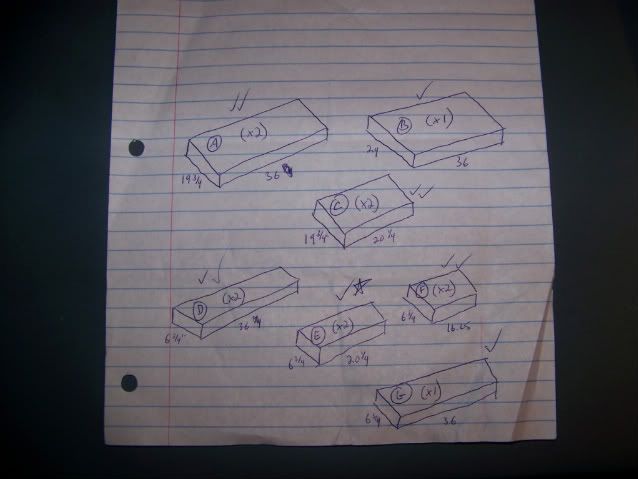

Next, I figured out the sizes for each cushion....

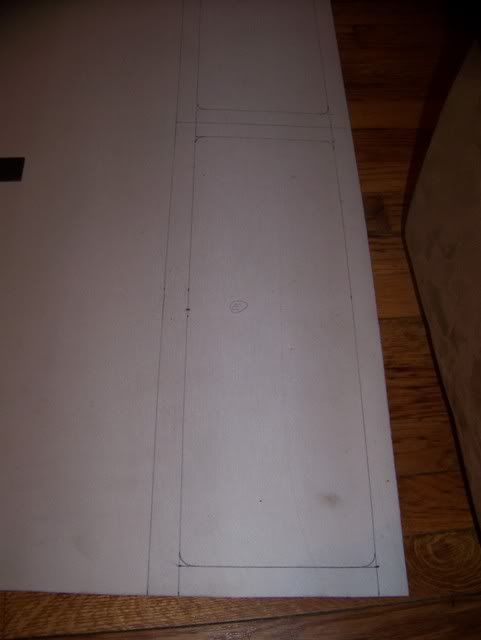

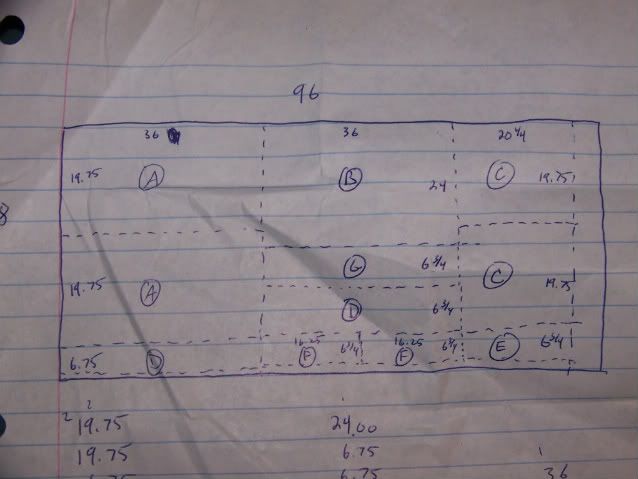

Then i figured out how to lay out the pattern on a sheet of ply. I decided to use 5/8" ply instead of 1/2", like most people use...i have a reason for that, but it is a surprise....

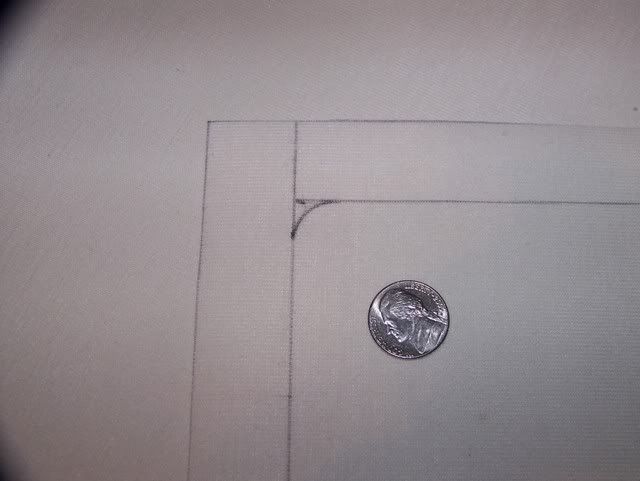

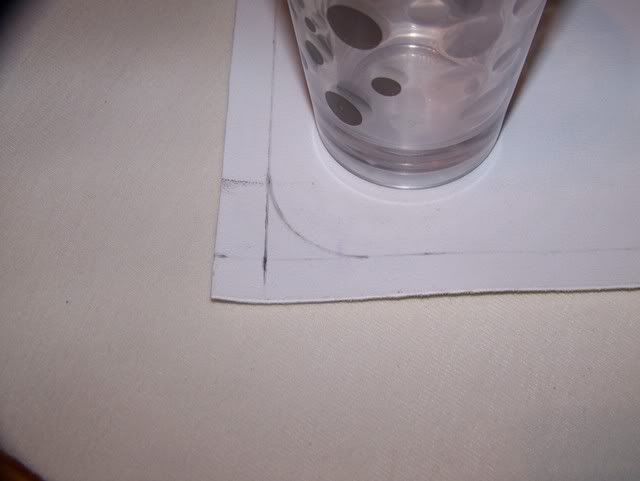

From there, each base was cut out and the edge rounded ( a nickle makes a great size guide for the corners)

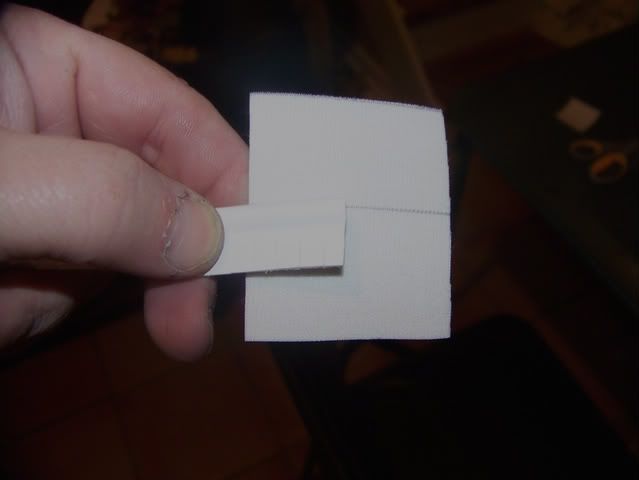

next step....laying out the vinyl patterns....

First, i sketched how up i wanted to have my seating arranged in the boat

Next, I figured out the sizes for each cushion....

Then i figured out how to lay out the pattern on a sheet of ply. I decided to use 5/8" ply instead of 1/2", like most people use...i have a reason for that, but it is a surprise....

From there, each base was cut out and the edge rounded ( a nickle makes a great size guide for the corners)

next step....laying out the vinyl patterns....