HMCM(SS)Ret

Cadet

- Joined

- Jul 1, 2010

- Messages

- 28

Howdy all! I've been reading and reading on this site. So am on information overload. New to boating (kind of funny,since I did 20 years in the Navy). So I bought this 26 foot trailerable houseboat last year (an emotional decission, which tend to bite me in the butt later). Used the boat last summer and ran fine but it always seemed a little heavier than i expected when towing and sat lower in the water than I thought it should. After reading on this site I did some closer investigation of the hull and transom. Yep, the floor, stringers and transom are rotted. In fact I am suprised the stern drive did not fall off the boat. Anyway, I have started on the terar down and rebuild. (pics to follow) The wood was heavy and wet and the foam was saturated. I seem to get conflicting advice re the use of PT plywood. Some say it is ok to use and others say never use it. So what is recommended?

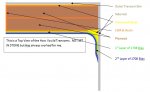

New to boating (kind of funny,since I did 20 years in the Navy). So I bought this 26 foot trailerable houseboat last year (an emotional decission, which tend to bite me in the butt later). Used the boat last summer and ran fine but it always seemed a little heavier than i expected when towing and sat lower in the water than I thought it should. After reading on this site I did some closer investigation of the hull and transom. Yep, the floor, stringers and transom are rotted. In fact I am suprised the stern drive did not fall off the boat. Anyway, I have started on the terar down and rebuild. (pics to follow) The wood was heavy and wet and the foam was saturated. I seem to get conflicting advice re the use of PT plywood. Some say it is ok to use and others say never use it. So what is recommended?