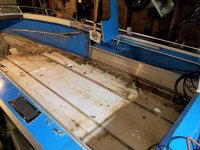

Floor foam removal complete. What a miserable job that is! First pressure wash of interior was completed as well. Found one pinhole in the floor near the transom. Looks like a corrosion spot, right under where the battery was located. Will inspect closer next work day, and post pics for some repair advice. Also near the bow when I pressure washed into the lap joints on either side, some dribbles appeared on the outside. I'm thinking if it's cleaned well, Gluvit or equivalent should solve that issue? The grunge from the wash water all settled to the bottom for this pic. It's since been shop vac'd out, and looks pretty decent.

The old fella that owned this boat prior was a 'handy' guy, particularly with wiring. Three different sections of wire connected the bow lights, with joints completed via hockey tape and wire nuts. I also found this very unique item under the carpet, no longer connected to anything onboard fortunately!

The old fella that owned this boat prior was a 'handy' guy, particularly with wiring. Three different sections of wire connected the bow lights, with joints completed via hockey tape and wire nuts. I also found this very unique item under the carpet, no longer connected to anything onboard fortunately!

Last edited: