Greetings from the Baltic Sea! So I'm a complete rookie and went to check my Bayliner '89 1950 today, to make sure everything is ok for the winter. It has been some freezing nights already. I'm a complete rookie and decided to do some routine (or should I say ruining) maintenance on my boat. These american made boats are very expensive here, one must pay at least $8000 for one, regardless of condition (rotten pos), so this rookie decides to take good care of his beloved beauty.

There is a thread of mine about one engine mount bolt being loose here. So I started by knock testing the transom, engine mount and stingers (which I can reach to) to map the rot process. Judging of the sound, transom has a couple of inches bad wood at the very bottom of the bilge. I think I'll try some wood rot fixing epoxy on that, as well as the stingers behing engine mount, which didn't sound very convincing either. Everything else which I could reach without removing the deck seemed to be fine according to the sound.

Before I get into the point, here is my HOWTO on filling your cylinders with antifreeze, in case you wonder how on earth that can be done.

1. Get that feeling you didn't completely manage to drain the exhausts as there is no drain plug at the bottom of the manifolds.

2. Decide you have to do something stupid to try and make things right.

3. Remove the bolts on top of the exhaust manifolds and fill them with antifreeze like on the picture below (notice the funnel).

4. Listen to the burping sound as some voids are filled, enjoying the thought that this was a good idea.

5. Unscrew the spark plugs to realize the cylinders are full of antifreeze.

My rookieness didn't end there, as I didn't do anything to remove the water from the cylinders before starting compression tests. Cranked the flywheel with a wrench, first cylinder showed 15 bars? Quite a high compression I thought, and as I released the pressure I got some antifreeze in my eye. Fortunately I used propylene glycol.

One cylinder on the port side showed no compression at all. I was quite panicked, as the reason I bought this boat was the only a couple of years old, powerful, adorable 350 v8. Next thing I knew I had the port side cylinder head in the trunk of my car.

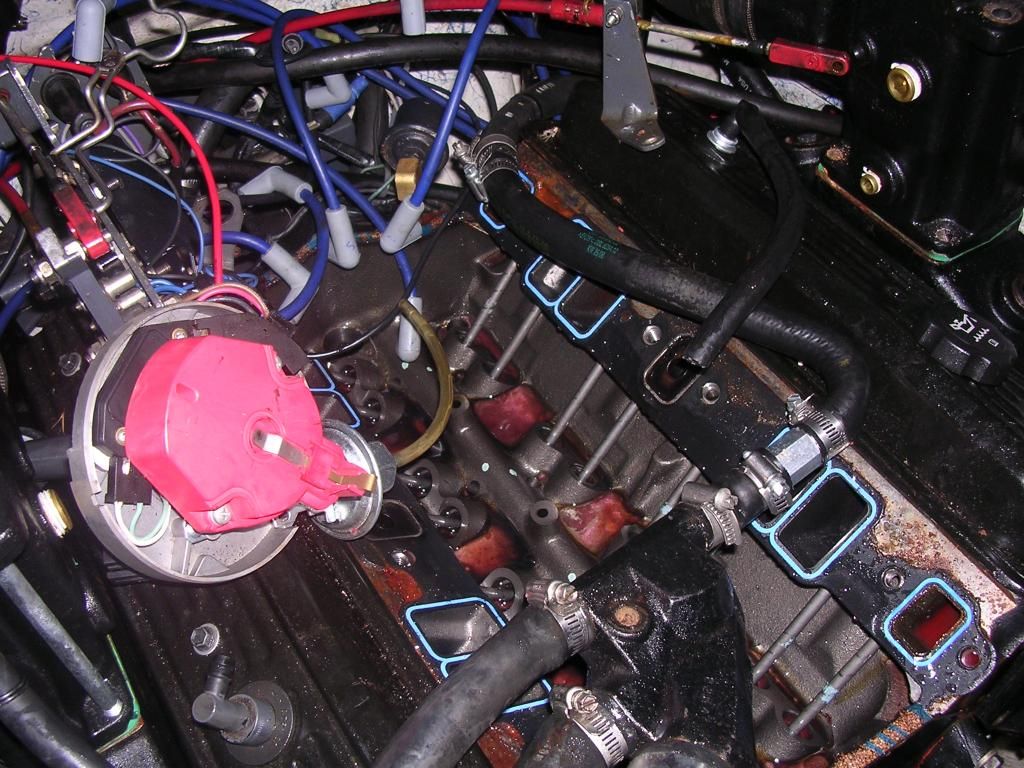

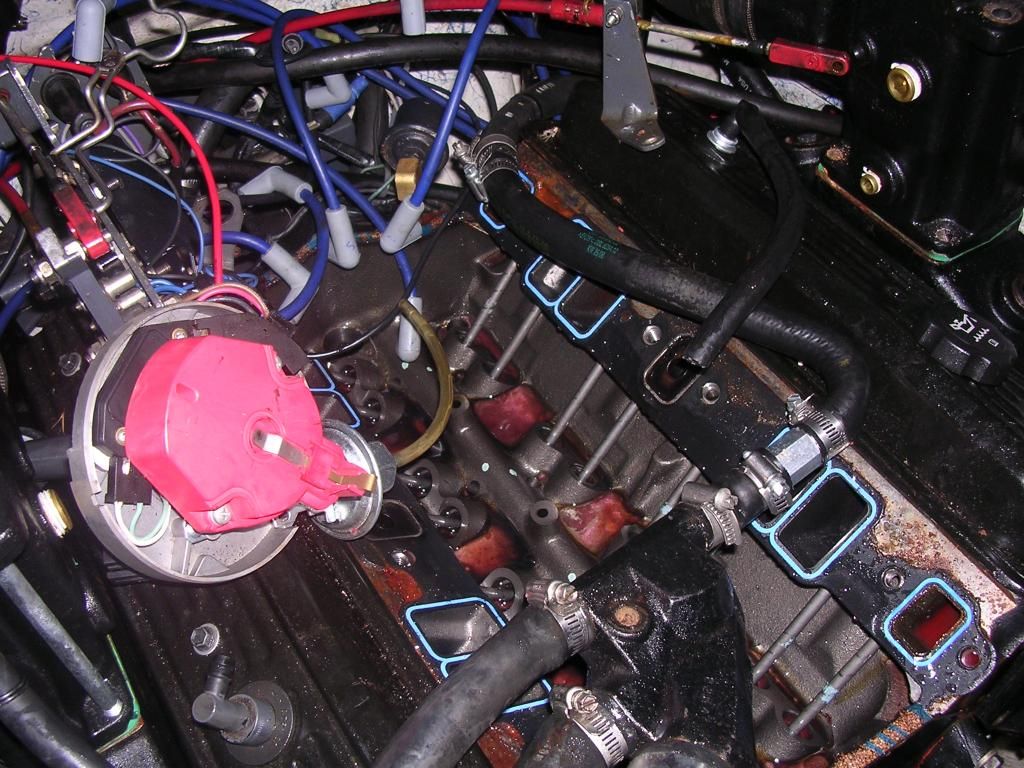

Carburetor removed, intake manifold next. Does anyone know where the other end of the vacuum hose goes to? When I removed the distributor, I didn't take note of it's location.

Intake manifold removed.

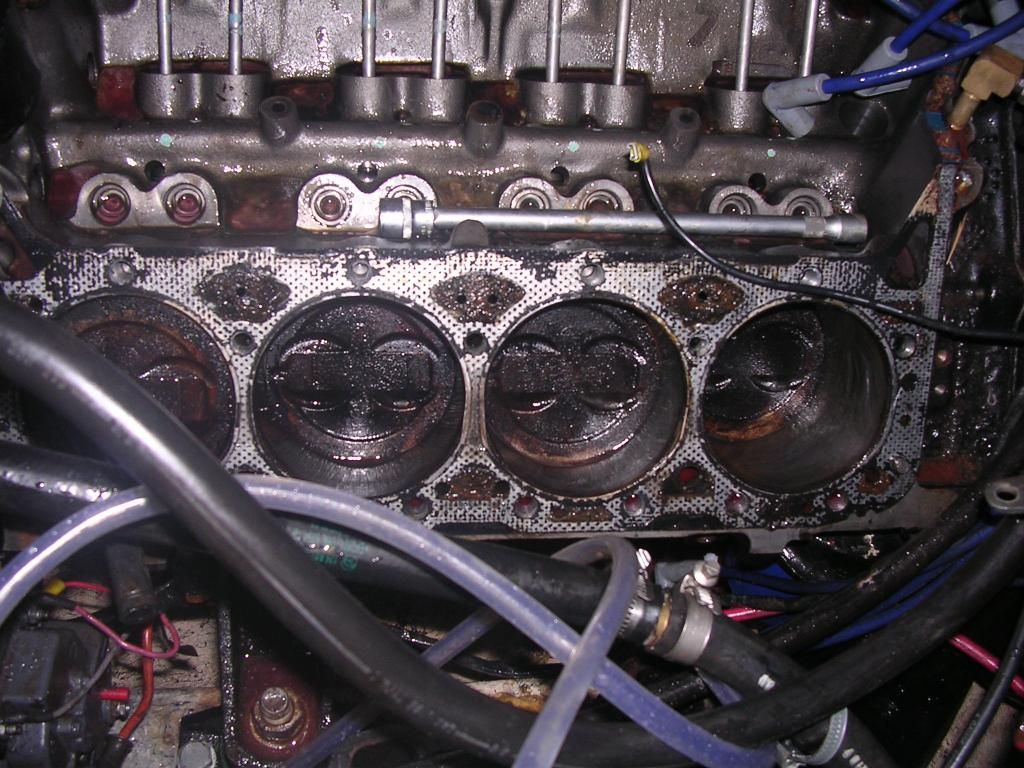

Here are some pictures of what I found (I don't think I found much, so I'm asking for your opinions on this):

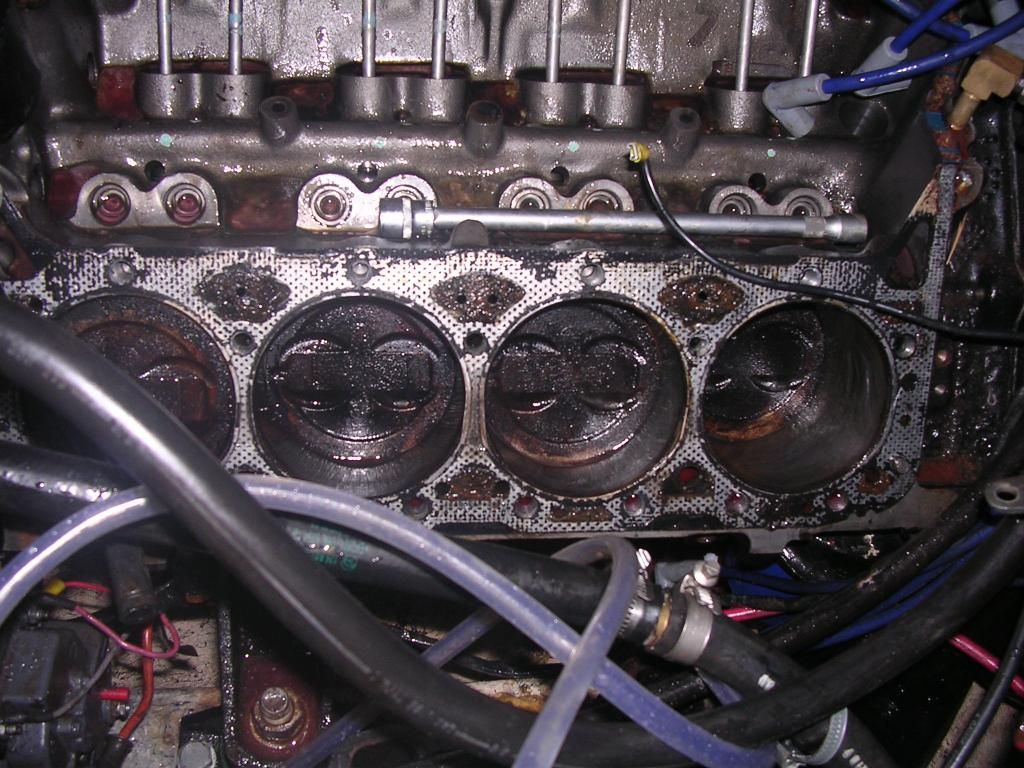

Head gasket still in place.

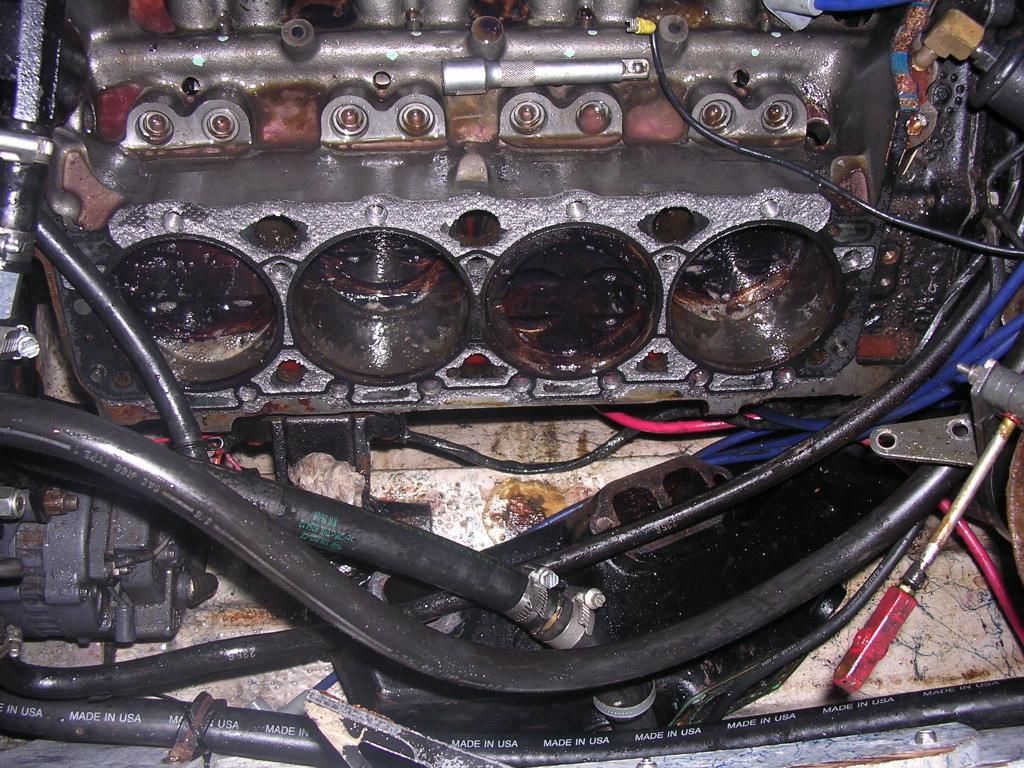

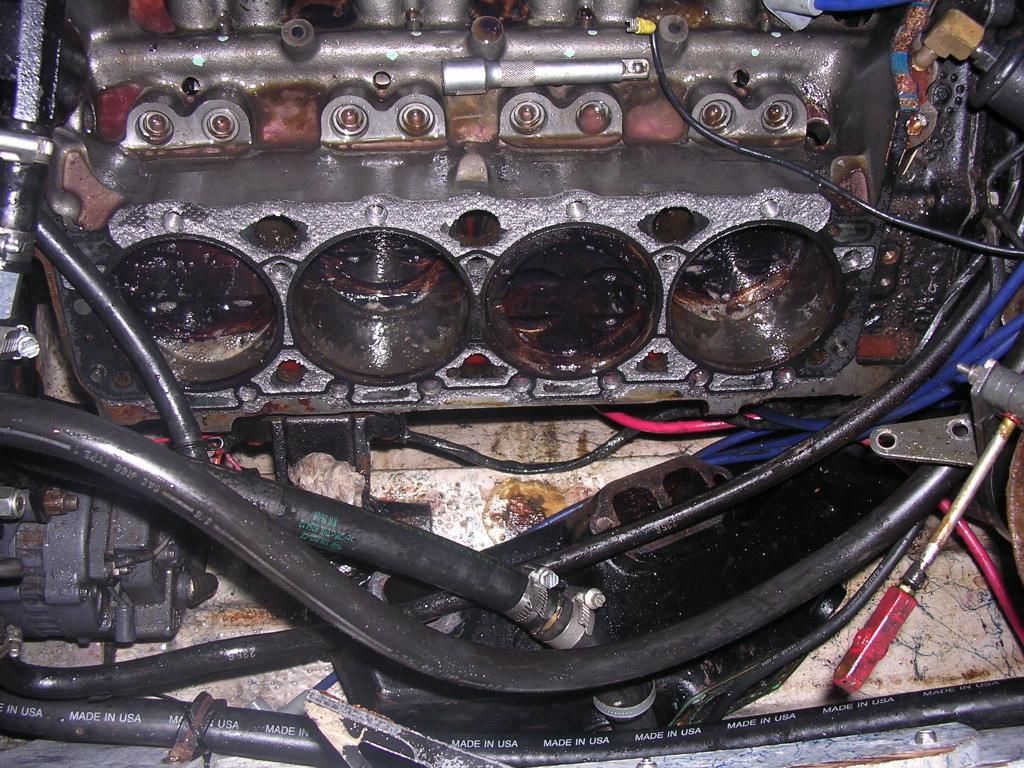

Gasket removed.

Other side of head gasket.

The cylinder with no compression was second from the right on first two pictures. Is the gasket blown from the middle of cylinders? I'm a bit confused, as the cylinder third from right had comparable compression to other cylinders (~5 bars). When winterizing the boat, my garden hose was bent and the water didn't circulate at all for a couple of minutes. Could that have blown the gasket? Could that be the reason of poor compression? Should I get the cylinder head planed before reinstall? On the starboard side, one cylinder had 4 bar compression, while others had 5. Should I remove that head as well?

Thank you for helping a fellow boater, who knows s**t.

There is a thread of mine about one engine mount bolt being loose here. So I started by knock testing the transom, engine mount and stingers (which I can reach to) to map the rot process. Judging of the sound, transom has a couple of inches bad wood at the very bottom of the bilge. I think I'll try some wood rot fixing epoxy on that, as well as the stingers behing engine mount, which didn't sound very convincing either. Everything else which I could reach without removing the deck seemed to be fine according to the sound.

Before I get into the point, here is my HOWTO on filling your cylinders with antifreeze, in case you wonder how on earth that can be done.

1. Get that feeling you didn't completely manage to drain the exhausts as there is no drain plug at the bottom of the manifolds.

2. Decide you have to do something stupid to try and make things right.

3. Remove the bolts on top of the exhaust manifolds and fill them with antifreeze like on the picture below (notice the funnel).

4. Listen to the burping sound as some voids are filled, enjoying the thought that this was a good idea.

5. Unscrew the spark plugs to realize the cylinders are full of antifreeze.

My rookieness didn't end there, as I didn't do anything to remove the water from the cylinders before starting compression tests. Cranked the flywheel with a wrench, first cylinder showed 15 bars? Quite a high compression I thought, and as I released the pressure I got some antifreeze in my eye. Fortunately I used propylene glycol.

One cylinder on the port side showed no compression at all. I was quite panicked, as the reason I bought this boat was the only a couple of years old, powerful, adorable 350 v8. Next thing I knew I had the port side cylinder head in the trunk of my car.

Carburetor removed, intake manifold next. Does anyone know where the other end of the vacuum hose goes to? When I removed the distributor, I didn't take note of it's location.

Intake manifold removed.

Here are some pictures of what I found (I don't think I found much, so I'm asking for your opinions on this):

Head gasket still in place.

Gasket removed.

Other side of head gasket.

The cylinder with no compression was second from the right on first two pictures. Is the gasket blown from the middle of cylinders? I'm a bit confused, as the cylinder third from right had comparable compression to other cylinders (~5 bars). When winterizing the boat, my garden hose was bent and the water didn't circulate at all for a couple of minutes. Could that have blown the gasket? Could that be the reason of poor compression? Should I get the cylinder head planed before reinstall? On the starboard side, one cylinder had 4 bar compression, while others had 5. Should I remove that head as well?

Thank you for helping a fellow boater, who knows s**t.

Last edited: