KesselRunner

Cadet

- Joined

- Jul 22, 2020

- Messages

- 24

Been working on restoring an old powerboat with a 2 stroke 115 hp outboard.

Recently installed the new plywood core in the transom. Did it from the inside using thickened epoxy.

My problem:

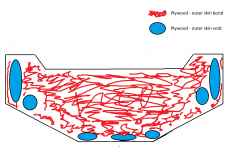

After the install it feels rock solid. But, I have found some voids where it seems I did not get enough clamping pressure. The location where I got a good bond and where there are voids between the plywood and outer skin can be seen in the attached figure.

Since the larger center regions of the transom got a good bond I do not feel like ripping it out again which I could only do by completely destroying both plywood and skin given that there is proper adhesion on the greater part of the surface.

As I see it I could either remove the skin in the regions where I have found voids from the outside which would allow me to do a real surface prepp, fill with thickened epoxy and then re-install the skin with bevelled edges and new glass.

Or I could just inject slightly thickened epoxy in these areas but I'd really like to hear some thoughts on how good that adhesion can be expected to be as I cannot sand the surfaces and the plywood has been covered in a layer of epoxy so it's actually a cured epoxy to cured epoxy bond that would be happening without any surface preparation.

Filling the voids to stop moisture from accumulating in these areas are of course something I will prevent by just filling these pockets with a syringe but what I want to make sure is that it is structurally sound. Advice and thoughts are much appreciated.

Recently installed the new plywood core in the transom. Did it from the inside using thickened epoxy.

My problem:

After the install it feels rock solid. But, I have found some voids where it seems I did not get enough clamping pressure. The location where I got a good bond and where there are voids between the plywood and outer skin can be seen in the attached figure.

Since the larger center regions of the transom got a good bond I do not feel like ripping it out again which I could only do by completely destroying both plywood and skin given that there is proper adhesion on the greater part of the surface.

As I see it I could either remove the skin in the regions where I have found voids from the outside which would allow me to do a real surface prepp, fill with thickened epoxy and then re-install the skin with bevelled edges and new glass.

Or I could just inject slightly thickened epoxy in these areas but I'd really like to hear some thoughts on how good that adhesion can be expected to be as I cannot sand the surfaces and the plywood has been covered in a layer of epoxy so it's actually a cured epoxy to cured epoxy bond that would be happening without any surface preparation.

Filling the voids to stop moisture from accumulating in these areas are of course something I will prevent by just filling these pockets with a syringe but what I want to make sure is that it is structurally sound. Advice and thoughts are much appreciated.