I understand your concern about voids, nobody likes or wants that.

You had epoxy between layers, right? its coated or protected, even if water gets in, It has to get in first, and if it does its in a pocket of epoxy void, you obviously painted or smeared it and it developed pockets.

So if water ever got in are you sure it would find unprotected dry unepoxied wood.

If it were me. and just m.h.opinion. IF I did or felt it was that big of a deal, you got to find it first and know you can fill each void to the top actually hitting the highest point of the void. thats a long shot. so you may only fill it 1/2-3/4 full. and thats same for all of them. so you still end up with voids.

I don't know if I would tear it out, your still better than it was at at tear out for repair.

you learned a lesson, keep an eye on it.

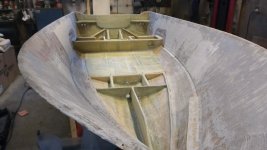

You know.... its reasonably difficult to laminate plywood and get 100% 0-voids.

Then you have to set that sometimes against a fiberglass skin be it inner or outer, then again not have any voids, and that again is difficult at best for 1st. timers.

You are not the only person that has had voids in a laminate.

Most never knew it or gave it a second thought. let alone consider tearing it back out.

Your choice. hope I was helpful, or gave a viable different angle of view.

best luck.

You had epoxy between layers, right? its coated or protected, even if water gets in, It has to get in first, and if it does its in a pocket of epoxy void, you obviously painted or smeared it and it developed pockets.

So if water ever got in are you sure it would find unprotected dry unepoxied wood.

If it were me. and just m.h.opinion. IF I did or felt it was that big of a deal, you got to find it first and know you can fill each void to the top actually hitting the highest point of the void. thats a long shot. so you may only fill it 1/2-3/4 full. and thats same for all of them. so you still end up with voids.

I don't know if I would tear it out, your still better than it was at at tear out for repair.

you learned a lesson, keep an eye on it.

You know.... its reasonably difficult to laminate plywood and get 100% 0-voids.

Then you have to set that sometimes against a fiberglass skin be it inner or outer, then again not have any voids, and that again is difficult at best for 1st. timers.

You are not the only person that has had voids in a laminate.

Most never knew it or gave it a second thought. let alone consider tearing it back out.

Your choice. hope I was helpful, or gave a viable different angle of view.

best luck.