JASinIL2006

Vice Admiral

- Joined

- Feb 10, 2012

- Messages

- 5,749

Re: Transom problems with Larson 186 SEI I/O Bowrider

Getting ready to grind some gel coat right now (ugh) to tab those edges. They're not quite a smooth as they appear in the pick, so I'm going to apply some PB to make a smooth transition.

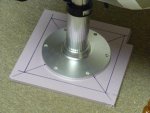

Fat Fanny, I didn't reinforce under the pedestal areas. There is a 3" wide fiberglass bulkhead just an inch or two forward of where the pedestal will rest, and I plan to build pedestal platforms out of two layers of 3/4" plywood. The platforms will be PB'd and glassed to the deck and the pedestals will be bolted to the platforms with bolts and T-nuts so there is no thru-deck holes.

Time to go tab in the bilge area...

Jim

Getting ready to grind some gel coat right now (ugh) to tab those edges. They're not quite a smooth as they appear in the pick, so I'm going to apply some PB to make a smooth transition.

Fat Fanny, I didn't reinforce under the pedestal areas. There is a 3" wide fiberglass bulkhead just an inch or two forward of where the pedestal will rest, and I plan to build pedestal platforms out of two layers of 3/4" plywood. The platforms will be PB'd and glassed to the deck and the pedestals will be bolted to the platforms with bolts and T-nuts so there is no thru-deck holes.

Time to go tab in the bilge area...

Jim