While the transom is off I am thinking of putting in an automatic bilge pump and being lazy and leaving the manual one in. Problem is I want to be really lazy and just use a T connect with a check valve to hook it into the existing output hose. I am going to go ahead and call myself out on that one and say it's not a good idea as the hose can only handle so much water flow and pressure, and if both were running I wouldn't get the max output, and could even burn one out.

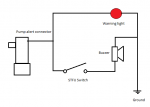

Sooo... I'll be putting in the automatic one and wiring in the manual override as well. I'll also be putting in the light and buzzer circuit below. My Paint skills are legend in some circles...

If there is no alert connector, I'll have to come up with something...

Part of the restore I think will involved an added circuit hooked to a float switch higher up then the pump. Like a catastrophic hull failure indicator alerting me that the water level in the bilge is higher than the main pump and it's probably overwhelmed so I should probably prepare to abandon ship. Oh, and of course wire it to a crash pump that can also be manually activated. We'd love to take it out on Lake Superior, but we need everything in place to ensure our safety and to buy us maximum time in an emergency. I like being over-prepared. I see it as a few extra bucks to buy a little more peace of mind about my family's safety.

For now, the automatic bilge pump, the above circuit, and call it good.