Finally!

I was able to get back to the boat toady to finish off the Manifold and Riser job. While all ended up well, great in fact, there were a few lessons learned. So, posting here for others if they undertake this job. Overall, it’s a straightforward job with no special tools needed but they are helpful.

Special Tools I used (1) thread chasers / cleaners. Not a tap but like a tap, these chasers are meant to clean up threads not cut new ones. I chased all the holes > the bolt holes in the heads as well as the new manifold where the riser bolts go. Even though its new, I wanted to make sure no issues in manufacturing as well as pull out any paint that is in there and will throw off the torque values. (2) hose removal tools, see

link. I got these some time ago and love them. Instead of jamming a screwdriver under the hose to break the seal, these tools are made for this and much easier to use. (3) NPT taps. I do not have NPT chasers so I used my taps to check the various NPT holes being careful to not go deeper. (4) Threaded rods.

This is a MUST IMO. I made mine from the old Riser bolts which are the same thread as the Manifold bolts. I just cut off the head and beveled it some. Was a perfect length. Need 2. You thread these into a couple of removed Manifold bolt holes both to remove and install the manifolds. NO WAY I could have done this job by myself without these. (5) Low value torque wrench. The torque values are 26 Ft-Lbs for the Manifold and 18 Ft-Lbs for the riser. Using a 200 Ft-Lb torque wrench is not going to cut it. Need one is the 0 to 50 Ft-Lb range.

Tips: to clean up the heads, I stuffed a paper towel in each exhaust port to keep out the crap. I left in the spark plugs. I also put a rag over the exposed Y=Pipe to keep stuff out. Cleaning out the bilge of all the scrapping debris was an absolute necessity. I also put painters’ tape on the new Manifolds with the word: RAG! to highlight that I needed to pull out the towels before installing the Manifolds. It’s also easy to forget that there are some clips and components that go under the Manifold and Riser bolts. You get it all installed and then realize you need to take out a bolt to put a clip on it. So, a hand drawn mock up of what goes where was used to keep track of that and referred to during install.

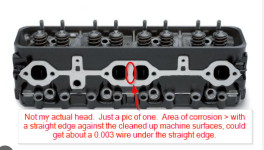

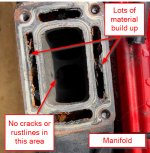

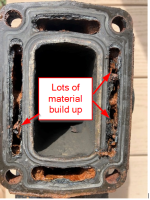

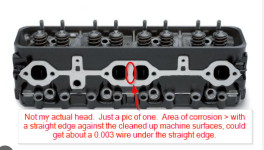

I used the Barr supplied gaskets and bolts except the Manifold bolts. I cleaned up (including chasing the threads) the original ones because I preferred the flange head style vs what was supplied (bolt with a lock washer). The Riser bolts have both a flat and lock washer. The Barr gaskets were of good quality, the Manifold gasket was of the Composite type > two layers of fiber material and a metal center layer. After cleaning the heads, I had about a 2 to 3 thou gap due to rust corrosion. See pic. The Manifold gasket has no external leaks. I assume it also filled this gap so no cylinder-to-cylinder leakage.

I did remove all paint on the Barr Risers and Manifolds mounting areas. I then checked the flatness of the Manifold (the face that bolts to the head) on a calibrated granite block and could not get under any area with a 2 tenths (0.0002”) feeler. Sweet!

I did buy After Market (AM) rubber couplers with the intention of replacing them. Measurement of the thickness showed the AM were slightly thicker so was feeling good about them. When going to install on the Y Pipe I noticed a loose fit, not good. Checking them to the OEM ones I discovered the Y Pipe couplers are different diameters on either end. And was the same with the AM ones. In other words, they only go on one way > they cannot be flipped. Since we are already supposed to be on the water, I did not take the time to measure the pipes. So, I resorted to re-using the OEM ones until I could figure out more about this.

Question: are the elbows and Y Pipe diameters different such that the coupler only goes on one way? They are not marked ‘this end up’.

Another surprise to me was I could not figure out how to install the exhaust elbow with its two rubber couplers (one to the Riser, other to the Y-Pipe) without removing the Riser. So, I settled on attaching the boot to the Riser, and elbow pipe to that boot and then the Y-Pipe boot to the other end of the elbow pipe. And then carefully slid it onto the Y-Pipe while getting the Riser set on the Manifold. I did this without the gasket in place, fearful I would nick it or push it into the bilge. Once the Riser was in place, I lifted it slightly and slipped in the gasket. Perhaps pushing the Riser to elbow boot all the way back on the elbow would have worked, unsure, as I was tired and simply needed to get it done. I did not use gasket sealer on the Riser gasket.

I had planned on replacing all the oil, water, and power steering hoses (including the PS cooler) when I did this job as pulling the Manifolds and Risers provides a lot more access, but due to my injury it put my schedule off. So, I will take that on next year and simply pull the Manifolds and Risers again.