OhioLowell

Petty Officer 2nd Class

- Joined

- Oct 21, 2005

- Messages

- 189

Hello all!

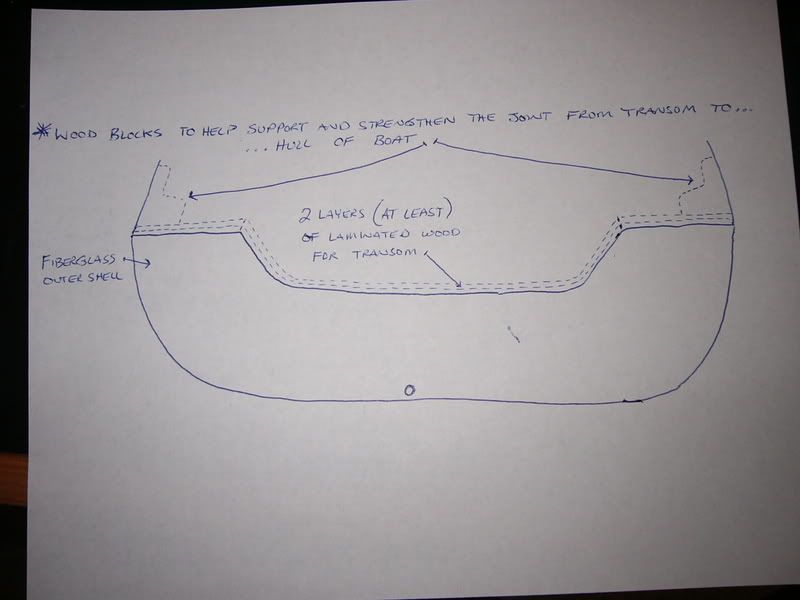

Well I took a few hours today while the kids were napping and removed the old stringers and those "cool" shelf barckets from the transom.

BEFORE!

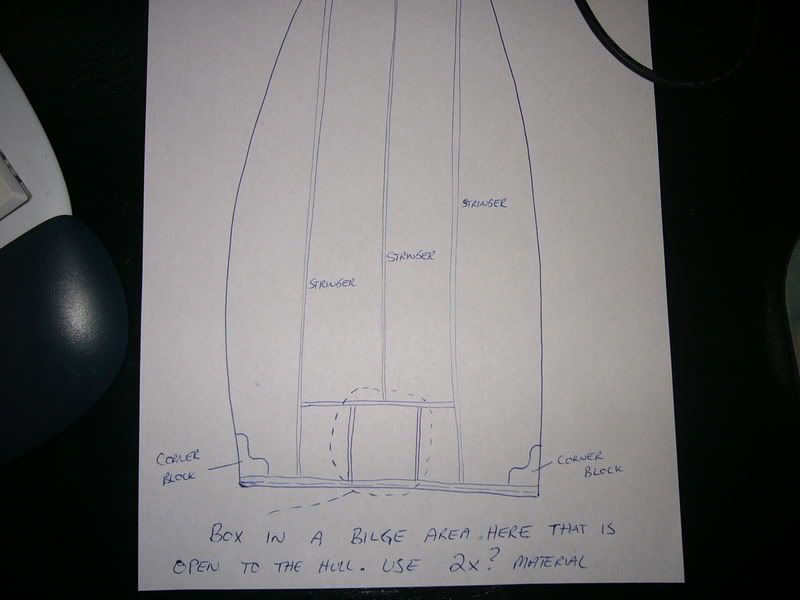

This is all 3 stringers!

Here is a shot of the interior of the transom now that the stringers and brackets are removed. Everything has been vaccumed out too.

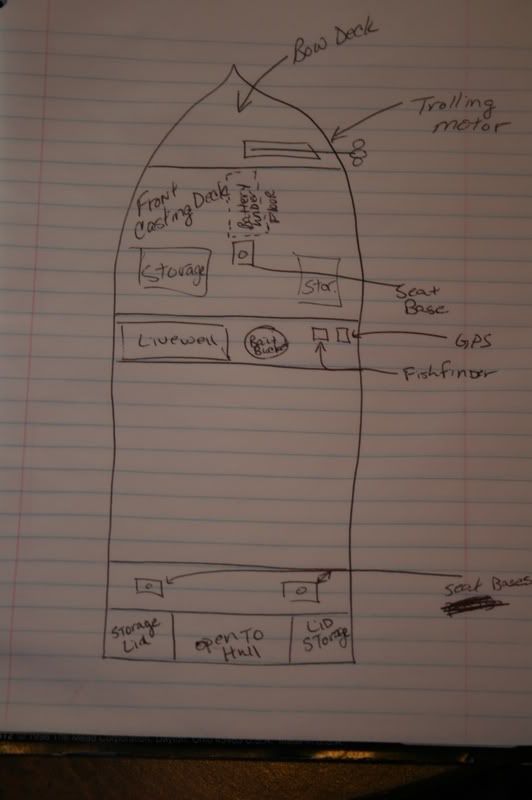

Here's a shot towards the bow.

THere are several places that when the stringers came out they pulled off some resin with them leaving the fibergalss exposed. Those are the white spots in the pictures. Beleive it or not, I didn;t even break any of the ribs removing the stringers. There are still several rusted out screws left in the ribs that will need to be removed.

Now I suppose I move onto grinding out the area under and around the stringers? It has occured to me that I don't know the best thing to accomplish this. I was thinking a 4.5" angle grinder with a 1/4" masonry wheel. (Would a wire wheel work for roughing up the ribs that are loose? These are not a flat surface and wouldn't be able to be ground with a flat wheel. )

Will it hurt anything to grind out these areas right now. They'll get glassed and finished once the transom comes off. They will be kept dry and clean until they're finished.

Also, do you think it would hurt anything to lay a layer of mat down under the new stringers? I figure this will help to repair any damage done while removing the old stringers.

Would you guys recommend using resin or epoxy for all of my repairs? I'm leaning more towards epoxy. I know it's more expensive but it seems to be ALOT stronger. Will epoxy stick to fiberglass for the repairs? Can you lay glass in expoy?

Thanks so much for your help!

Lowell

Well I took a few hours today while the kids were napping and removed the old stringers and those "cool" shelf barckets from the transom.

BEFORE!

This is all 3 stringers!

Here is a shot of the interior of the transom now that the stringers and brackets are removed. Everything has been vaccumed out too.

Here's a shot towards the bow.

THere are several places that when the stringers came out they pulled off some resin with them leaving the fibergalss exposed. Those are the white spots in the pictures. Beleive it or not, I didn;t even break any of the ribs removing the stringers. There are still several rusted out screws left in the ribs that will need to be removed.

Now I suppose I move onto grinding out the area under and around the stringers? It has occured to me that I don't know the best thing to accomplish this. I was thinking a 4.5" angle grinder with a 1/4" masonry wheel. (Would a wire wheel work for roughing up the ribs that are loose? These are not a flat surface and wouldn't be able to be ground with a flat wheel. )

Will it hurt anything to grind out these areas right now. They'll get glassed and finished once the transom comes off. They will be kept dry and clean until they're finished.

Also, do you think it would hurt anything to lay a layer of mat down under the new stringers? I figure this will help to repair any damage done while removing the old stringers.

Would you guys recommend using resin or epoxy for all of my repairs? I'm leaning more towards epoxy. I know it's more expensive but it seems to be ALOT stronger. Will epoxy stick to fiberglass for the repairs? Can you lay glass in expoy?

Thanks so much for your help!

Lowell