Work has slowed down tremendously on the Merrilee. As of the last post at the beginning of July, our intent was to take it out a second time in the last week of July. Getting all the trim on and at least two coats of varnish was paramount for that timeframe. The week prior to the planned second splash, our new first mate decided he wanted to be born 6 weeks early and of course all the boat plans get dropped. Fortunately progress had been made that the boat was ready to go in the water as he was born and so hopefully we can get a day this fall yet to get it wet and test out the new steering and other improvements.

All hope is not lost, though. If you recall, there are two people working on this project and my dad has been able to make some progress on some pumps and other stuff.

Our boat registration FINALLY came in June (Thanks PA Fish and Boat commission), and I was able to get the registration plate built. While the rest of the front deck is finished in varnish, the registration plate is actually coated with epoxy. Since the registration sticker will need to be replaced over time (and I use a blade to do so), the extra durability of the epoxy was desirable to permit that. This panel is actually magnetically attached to the deck. When we want to take photos, we can remove it to look more period, and then snap it in to place when we need to be out on the water.

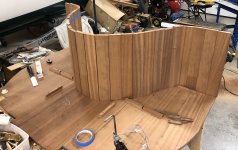

Here you can see the completed trim (partially sanded), particularly worthy of note is the bead that runs along the bottom to ensure a smooth uniform look at the bottom of the wood, it allows me to hide slop and other inconsistencies.

Some of you may recall the first splash video my reference to the steam gauge not working correctly. We purchased and piped in a brand new gauge that while it is not as period as the previous one, allows us to get out on the water until we are able to fix up the original. It will also serve as a backup in the event that the other one fails.

There are two pumps that are powered by the engine, one is a vacuum pump (right) and water pump (left). These both receive power from the up and down motion of the cylinders. The water pump will move water from the holding tank to the boiler, and the vacuum pump creates a vacuum on the exhaust of the engine to assist in pulling steam through and out of the engine, making it run more efficiently. The link to power these is being built now and the hope is that we can get one or both of them piped in to work by the time we would take it out yet this fall.

As for the water pump, it is the second of three methods to get water in the boiler. We use an injector which uses a series of valves and steam to replenish water (if the boat is stationary). This was installed and operable last fall. This almost-complete pump will provide water while the engine is running (not using additional steam so it is more efficient because you are already running the engine). The third one which will be it's own mini project is essentially another very little steam engine on one side and a pump on the other end. It will also allow us to move water when the boat is stationary. Since having water in the boiler is very critical, it will be nice to have three different options to do so.

Those are the updates for now - I really wanted to be able to post about a month ago with the video of splash number 2 and say that the steering worked great, but obviously we had a change of plans. Stay tuned this fall as hopefully we can find a day to get this out on the water again.