BOYS & TOYS

Petty Officer 2nd Class

- Joined

- Mar 1, 2008

- Messages

- 141

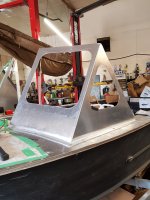

I found this site very helpful to makeover this 18ft Holiday so I thought maybe someone else could get inspiration from some pictures. I will try to answer any questions. I'll try to post in order of repairs.

It has been used each summer since I picked it up so its a longtime rebuild.

It had a older 65hp Mercury mounted on it and a 1999 125hp Mercury that came with.

It has been used each summer since I picked it up so its a longtime rebuild.

It had a older 65hp Mercury mounted on it and a 1999 125hp Mercury that came with.