No Title

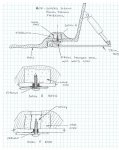

Did some more demo work. As I mentioned, I had removed a couple of 1' square sections of the battery bunk to see what was underneath. The wood is drying out in that area nicely. A lot of water held up in the foam. So my goal is to get all of the foam pulled out. There are several little outriggers from the stringer that were only held in place with the foam. You can see two of them in the pictures here. They are not glued or glassed in. Just a tab keeps them located on the stringer. Unfortunately to get to the foam forward, I am going to need to pull the decking under the cushions in the rear salon (aft berth). Wife isn't going to be happy. I'll just make quick work and get it covered back up before she sees. Removing the foam is a pain in the butt.

I also need to get the remaining rear deck removed to see if the screws from the trim tabs poke through the hull and are the source of water. Weather is turning cold for a few days. So no work until next weekend.

Did some more demo work. As I mentioned, I had removed a couple of 1' square sections of the battery bunk to see what was underneath. The wood is drying out in that area nicely. A lot of water held up in the foam. So my goal is to get all of the foam pulled out. There are several little outriggers from the stringer that were only held in place with the foam. You can see two of them in the pictures here. They are not glued or glassed in. Just a tab keeps them located on the stringer. Unfortunately to get to the foam forward, I am going to need to pull the decking under the cushions in the rear salon (aft berth). Wife isn't going to be happy. I'll just make quick work and get it covered back up before she sees. Removing the foam is a pain in the butt.

I also need to get the remaining rear deck removed to see if the screws from the trim tabs poke through the hull and are the source of water. Weather is turning cold for a few days. So no work until next weekend.