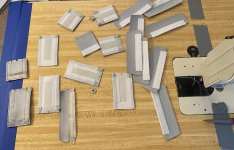

Another 'trick' that I've come up with and thought to share with those who also do upholstery . . .

Some areas of a skin/cover are subject to a bit of stretching during installation, usually in the areas of wrap-around corners. Since the thread is PTFE (ie Teflon) is is prone to slipping at the ends of a seam, even with back-stitching. the seam can/does start to come apart.

As a solution, I have added 'staples-as-rivets' in some of the stress areas. The armrests need to be turned right-side out after sewing and that puts a bit of stress on the velco flaps, as does the actual fitting of the skin to the armrest itself.

I placed 4 SS staples and closed them up on the back-side to keep the stress from tearing out the seams during handling.

.

.

.

This skin is for the captain's helm seat (identical), which is still in the boat, and may be an afternoon project to remove.