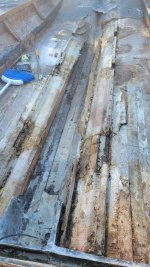

Picked up this 1981 hustler skip jack, 14', 60hp mariner. Engine good, Lowrance depth finder works, minn kota mid 80's trolling motor works. However, all wood, all is rotten so here I go.

Read alot of posts on here bout transoms and stringers, very helpful info.

Never done a boat let alone fiberglass, I spent 2 1/2 yrs rebuilding a 64 Impala SS with no previous experience so let's try a boat..

Read alot of posts on here bout transoms and stringers, very helpful info.

Never done a boat let alone fiberglass, I spent 2 1/2 yrs rebuilding a 64 Impala SS with no previous experience so let's try a boat..