Dantana Tin

Seaman

- Joined

- Mar 21, 2015

- Messages

- 61

This is my first post to the Starmada.

I was wondering if anyone has re-enforced the gunwales on their Starcraft or other aluminum boat. I am the proud owner of a 1967 18' Holiday V. I currently have scotty rod holders installed in the gunwales and they seem kind of flimsy (the gunwales). I thought about using wood underneath them to reinforce it, but not sure if it's a good idea and if so what type of wood would be best.

I have just rebuilt the 1967 little dude trailer that my holiday sits on (wife calls her "the mistress"). I even had to replace the axle due to the inability to replace the (obsolete) hubs. So she has been completely re-wired with new leds all around, spare tire holder, trailer jack wheel, and the fenders stripped and repainted. The boat floor has been removed and I am working from the inside hull out now. I am also going to need to re-wire the rats nest that some would call "boat wiring". I was wondering if someone knows of a good resource for wiring diagrams and wiring.

Also I'm on the lookout for a glove box door for my Holiday as well.

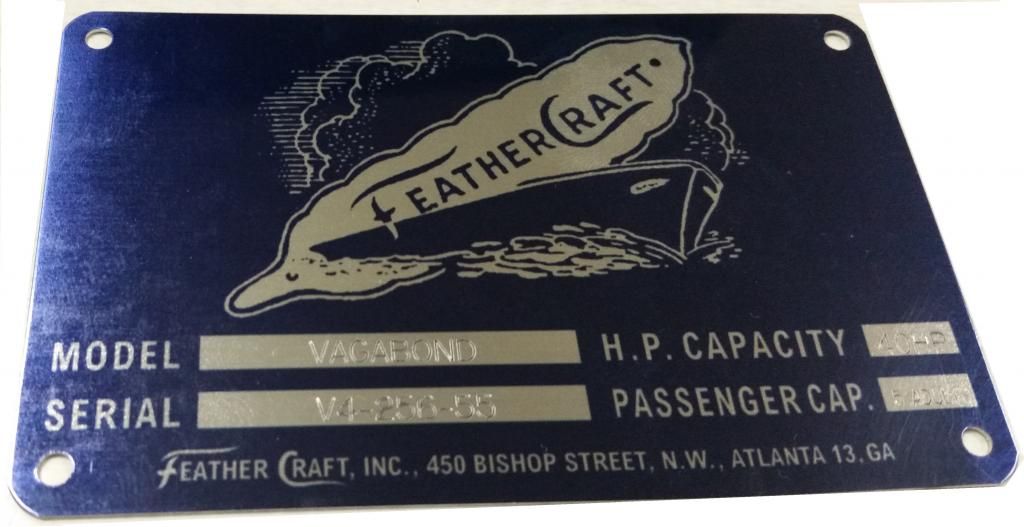

This is slow going since I'm a disabled veteran and something's don't work like they used to. But you just gotta take it on one task at a time. The picture below was how I found her. I hope to have some more pictures up and added soon, if I can figure that out. GA_Boater was awesome in helping me get this far.

Thanks for any help/feedback.

I was wondering if anyone has re-enforced the gunwales on their Starcraft or other aluminum boat. I am the proud owner of a 1967 18' Holiday V. I currently have scotty rod holders installed in the gunwales and they seem kind of flimsy (the gunwales). I thought about using wood underneath them to reinforce it, but not sure if it's a good idea and if so what type of wood would be best.

I have just rebuilt the 1967 little dude trailer that my holiday sits on (wife calls her "the mistress"). I even had to replace the axle due to the inability to replace the (obsolete) hubs. So she has been completely re-wired with new leds all around, spare tire holder, trailer jack wheel, and the fenders stripped and repainted. The boat floor has been removed and I am working from the inside hull out now. I am also going to need to re-wire the rats nest that some would call "boat wiring". I was wondering if someone knows of a good resource for wiring diagrams and wiring.

Also I'm on the lookout for a glove box door for my Holiday as well.

This is slow going since I'm a disabled veteran and something's don't work like they used to. But you just gotta take it on one task at a time. The picture below was how I found her. I hope to have some more pictures up and added soon, if I can figure that out. GA_Boater was awesome in helping me get this far.

Thanks for any help/feedback.