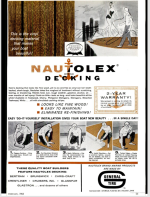

Just as a follow-up, the Nautolex install on my deck panels is now complete. There are some pics and further details in the project thread in signature below.

I ended up using the ducan Dek-Master trim adhesive, which is a contact cement. By working carefully, with a second person to assist, the bonding process worked out fine, with no issues. I did end up wrapped the fore and aft edges around and bonding and stapling to the backside of the panel. The sides I left hang past to the edge of the ply about an inch and a half, just to block that gap between the hull and the panel. The side panels will keep crap out of that area along the main section of the hull, but up under the consoles, and in the forward deck area I thought this flap might keep pine needles, dirt, and other debris from making its way below-deck.

When riveting the deck panels in place, I'm assuming a dab of 5200 goes on each rivet? If so, what's the suitable product for wiping up 5200 residue, but not damaging the vinyl?