classiccat

"Captain" + Starmada Splash Of The Year 2020

- Joined

- Dec 20, 2010

- Messages

- 3,412

Once the strip is screwed in place from 1 side, I was able to start going to town with the dead-blow, starting at edge where it's screwed-in...getting the aluminum strip to conform to the keel. As I was doing this, I had to keep tightening down the 8/32's since the gap between the alum patch & keel would close-up.

Once I got it to the other side, drill/tap/screw more 8/32's in place.

This is the time to get all of the finish-pounding in because you can always tighten the screws back-up if they're made loose. You're s.o.l. if a blind-rivet loosens-up.

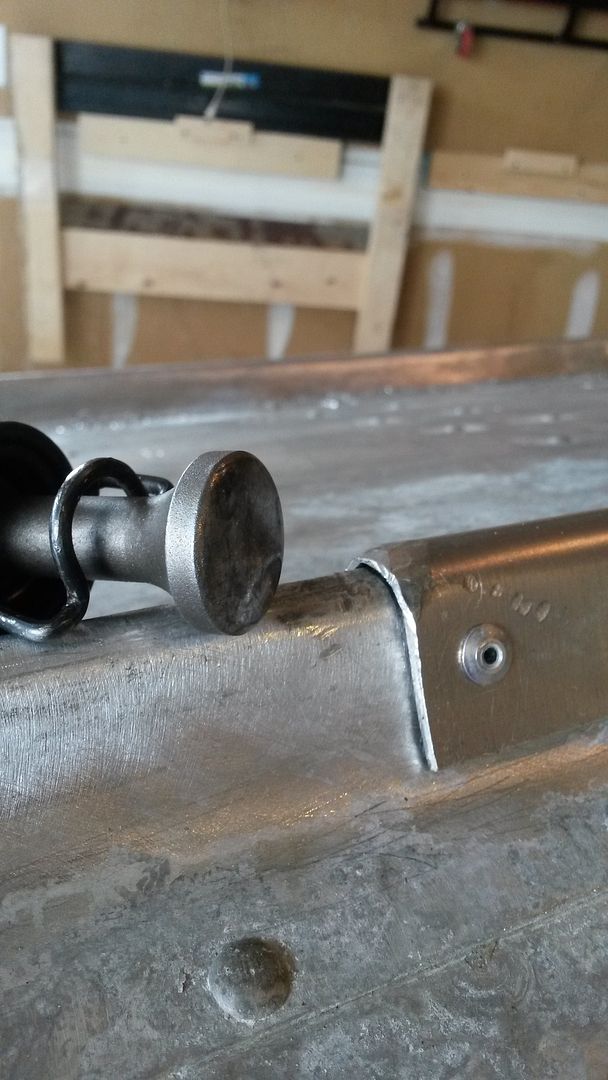

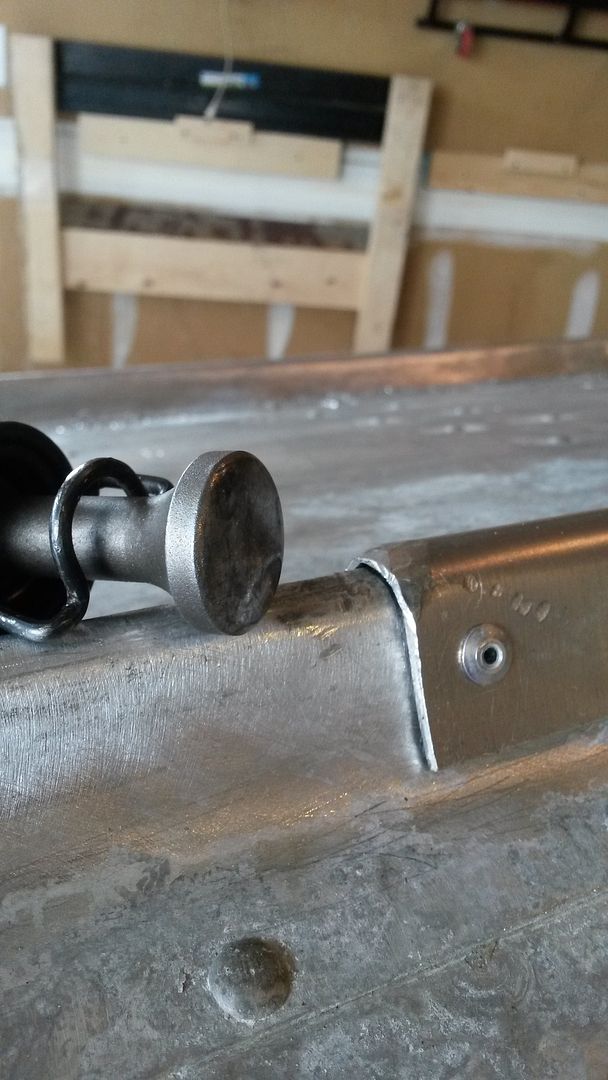

Like flattening the ends down with the riveting hammer:

The final stretch is putting-in the closed-end blind rivets (All aluminum).

^^^ the results exceeded my expectations by a mile!

Thanks for stoppin' by! :yo:

Once I got it to the other side, drill/tap/screw more 8/32's in place.

This is the time to get all of the finish-pounding in because you can always tighten the screws back-up if they're made loose. You're s.o.l. if a blind-rivet loosens-up.

Like flattening the ends down with the riveting hammer:

The final stretch is putting-in the closed-end blind rivets (All aluminum).

^^^ the results exceeded my expectations by a mile!

Thanks for stoppin' by! :yo:

Last edited: