danoutbard

Petty Officer 3rd Class

- Joined

- Nov 18, 2011

- Messages

- 87

Re: Johnson 90 will not go over 2200 rpm at wot in the water after complete overhaul

Excellent point

Thanks

Excellent point

Thanks

That's a bubble back 1985 90HP right? Crossflow?

No SLOW on that one.....

So, what about some pressure lost through these bolts, it would make suction too low to suck gaz through the high speed jet on the card.

in the garage to replace the vro, but it has only 2 nipples. I red here that i can cancel the vacuum pulse line and we're ok. Can somebody give me confirmation on that please ?

in the garage to replace the vro, but it has only 2 nipples. I red here that i can cancel the vacuum pulse line and we're ok. Can somebody give me confirmation on that please ?

Ok, had time to work on the motor (J90tlcos) this week-end, here's what

i did.

Did a spark test: spark does jump 7/16" on all cylinder View attachment 135768

While motor running (with the flush), i pulled the plug cable one at the time to see if this had any effects: pulling cable 1 & 2 and an effects but pulling 3 & 4 (left bank) had barely no effects ? Remender that spark is good on every cylinder and compression is at 120 psi + -

it is normal for heat to rise and top cylinders to be hotter than bottom ones.

Also, touching the block at cylinder 1 is hot but just warm at cylinder 3

What is that device? I cannot see how you would test spark on the motor with that.

Here is what I use. There is no spark plug anywhere when using the spark gap tester...

View attachment 135774

Something wrong here. One and three are the starboard bank, and 2 and 4 are the port bank.

goes tlike this:

2______1

4______3

So, you got the coils reversed on the head. I think you have #2 and #4 coils sparking the wrong cylinders. Just swap the spark plug leads to verify. If you do, I am surprised it is not backfiring like crazy.

switch the carbs, and see if the non effect from pulling the plug wire follows the carb.

if so re- rebuild those carbs...and look very carefully at everything....all the little passages and ids in the jets make sure the needles are not bent or clogged

good luck

bob

I've lost track.... On the previous (pg 1) page, "emdsapmgr" suggests that you have the engine running, then remove a plug wire from a spark plug (one at a time) to observe the resulting rpm drop. This would reveal what cylinder is and is not firing properly. I have seen no mention of that test being performed... perhaps I overlooked it?

If it has not yet been performed, do so and let us know the results.

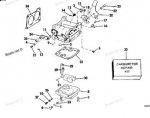

In your diagram (above post #37) #4 is the slow speed jet(s) 2 to a carb... and #33 is the high speed jet(s) 2 to a carb. There are no adjustable needle valves on that model.